LESSON 2

TOPIC : PRODUCTION OF MATERIALS.

CONTENT:

1. Production of Wood Materials, Timber Growth and Felling.

2.Properties of good timber preservatives.

3. Common timber defects, twist, bowing, cupping, etc

4. Methods of cutting veneers

5. Types and manufacture of laminated boards

Production of Wood Materials, Timber Growth and Felling.

Wood is one of the oldest materials in technology. It is composed of cellulose, lignin and other minor materials such as starch, resins, wax and gum. When closely observed, wood is seen to be made up of tiny thread-like units called fibres.

Wood is classified as either hardwood or softwood. The older the tree, the bigger it becomes. When the trees become mature, it is felled by the use of axe or chain saw and sliced into standard market sizes for different purpose in furniture making and construction of buildings.

Hard Wood:

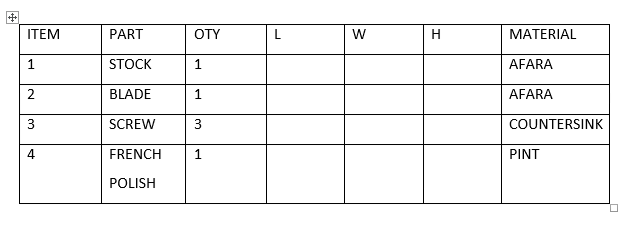

Hard Wood: These are got from deciduous tree. They have broad leaves and their seeds are enclosed in cases. Some examples include Mahogany, Afara, Opepe, Abura, Omo, Agba, Sapele, Oak, Jarrah and Teak.

Soft Wood : These are got from coniferous trees (i.e. trees that bear naked seeds which are in cones). They have narrow leaves and grow in the temperate regions of the world. Examples include cedar, pine, fir, larch, spruce and European whitewood.

Tree Growth: Trees undergo two types of growth:

1.

Primary or vertical growth. This takes place mainly near the tips of the root and shoots of the tree and continues for the most part of the plant’s life.

2.

Secondary or horizontal growth. This results in increase in girth and takes place mostly in the cambium.

The stages of processing wood before becoming useful are:

i. Felling

ii. Conversion

iii. Seasoning

iv. Preservation.

TYPES OF TREE:

Deciduous Tree = Hard wood

Coniferous Tree = Soft wood

THE MAIN PARTS OF A TREE.

1) The Roots

2) The Stem / Trunk

3) The branches

4) The bark

5) The Leaves

The felling of trees for timber use is done broadly in two areas in Nigeria.

I. The Free Area

II. The Forest Reserve Area.

1.

The Free Area: This is the area outside the forest reserve area and it is owned by individuals. The amount of money paid to the government by the timber contractor for permission to cut down any tree in the Free Area for commercial purposes is called Tariff.

2.

The Forest Reserve Area: This is the government owned area. The forest reserved area is guarded by the forest guards. Hence, it is difficult for anybody to cut down any tree in the forest reserve area without the permission from the government. The amount of money paid for the timber to be cut down in the forest reserve area depends on the volume of the trees to be cut down. Hence, this is termed O.T.V i.e Out Turn Volume.

The portable powered saw used in cutting down trees is called Chain saw.

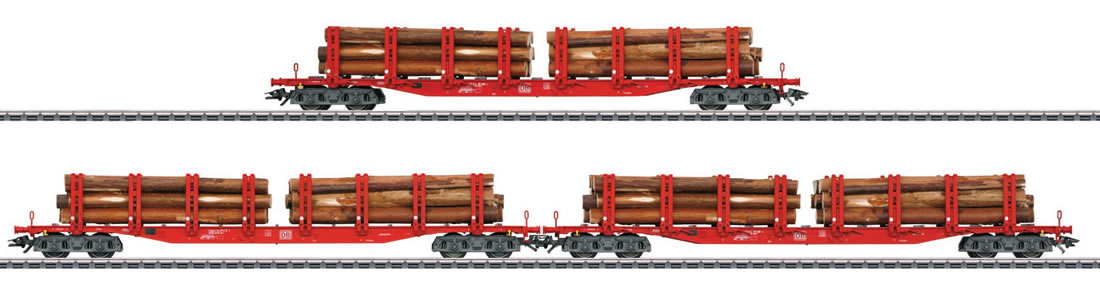

METHODS OF TRANSPORTING LOGS.

Logs are transported from the forest to sawmill, where they are sawn into the required lengths and sizes of planks. Methods of transporting logs are:

I. By Road Transport

II. By Train

III. By Waterways.

CONVERSION OF WOOD.

CONVERSION OF WOOD.

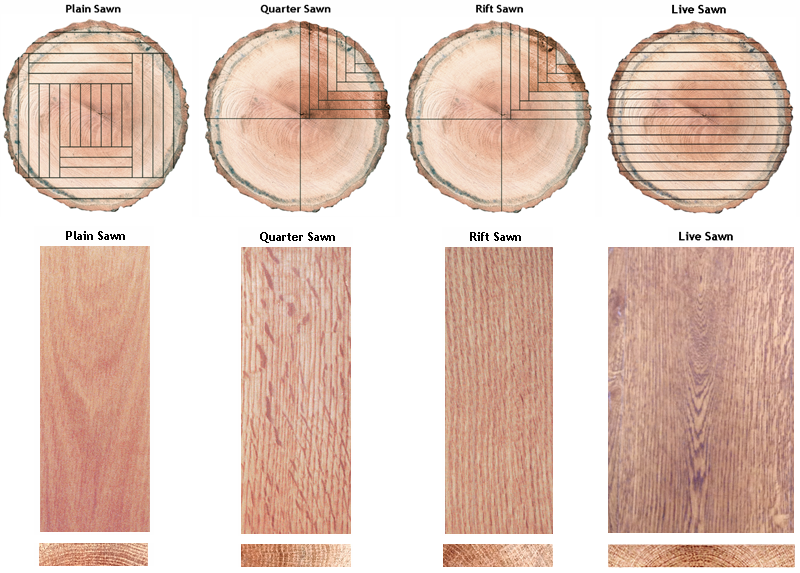

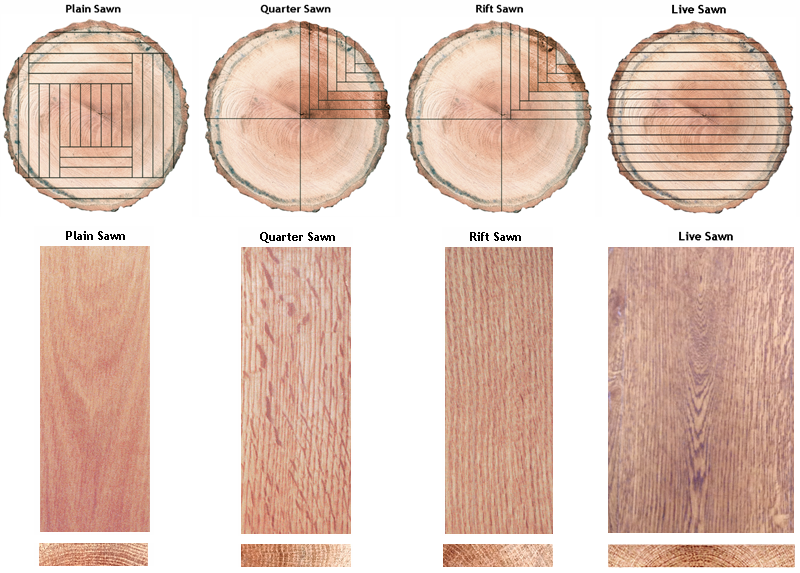

The conversion of wood is the process of sawing logs of timber with wood working machines (Sawing machine) in the Sawmills into planks of required size or marketable size or commercial sizes. The popular methods of conversion of logs of timber into planks are:

I. The plain (through and through) method

II. The quarter sawn method

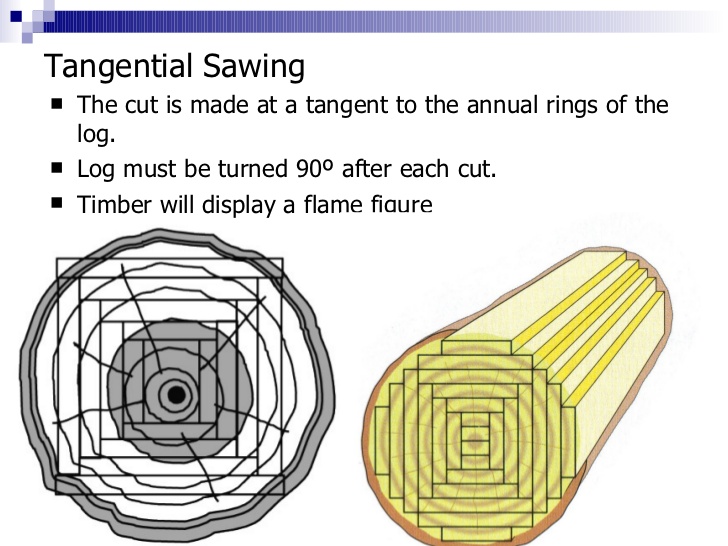

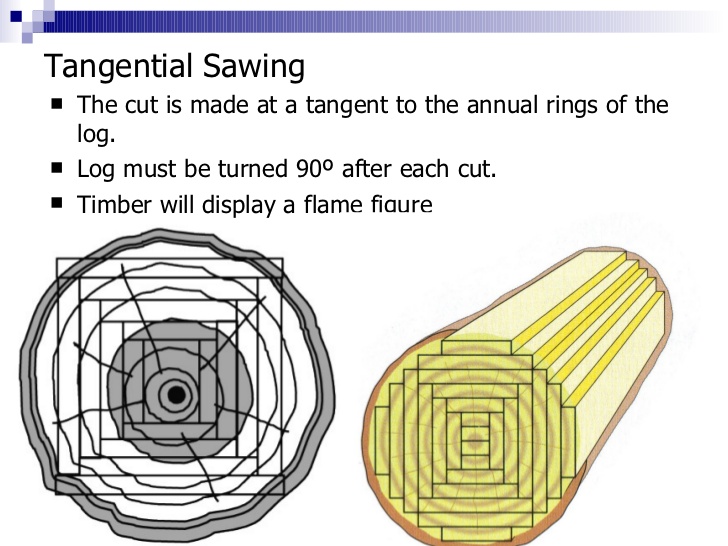

III. The tangential sawn method

1.

Plain Sawn Method: The plain sawn method is also known as through and through method. In plain sawn method, planks are sawn parallel to the axis of the tree trunk. This method of sawing planks is used for producing planks which are needed for doors, windows and roofs of houses. The planks are cut parallel to the axis of the wood.

2.

Quarter Sawn Method: This method is simply the sawing of timber plank after plank. The Quarter sawn method is the method of conversion of timber along the rays of the wood. In quarter sawn method, planks are cut at right angles to the growth rings. This method of sawing planks is used for producing planks which are cut with the growth rings running through the thickness of the planks.

3.

Tangential Sawn Method: Tangential sawn method of sawing planks in which the planks are cut so that their wide edges are tangential to the growth rings.

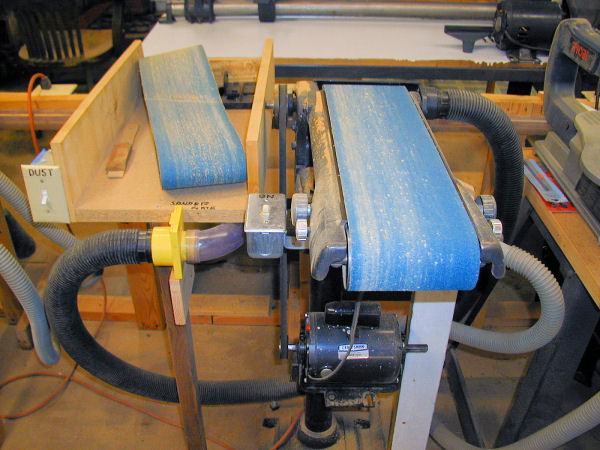

Some of the machines used for conversion of trees are:

a) The circular saw

b) The horizontal log band saw

c) The vertical log band saw

d) The frame saw.

SEASONING OF WOOD.

SEASONING OF WOOD.

Wood contains a great deal of water. The water content must be reduced by a process known as seasoning before the wood can become useful. Seasoning of wood is the process of drying or reducing the excess water in the wood. The excess water is called moisture content.

Methods of seasoning wood:

There are two methods of seasoning wood.

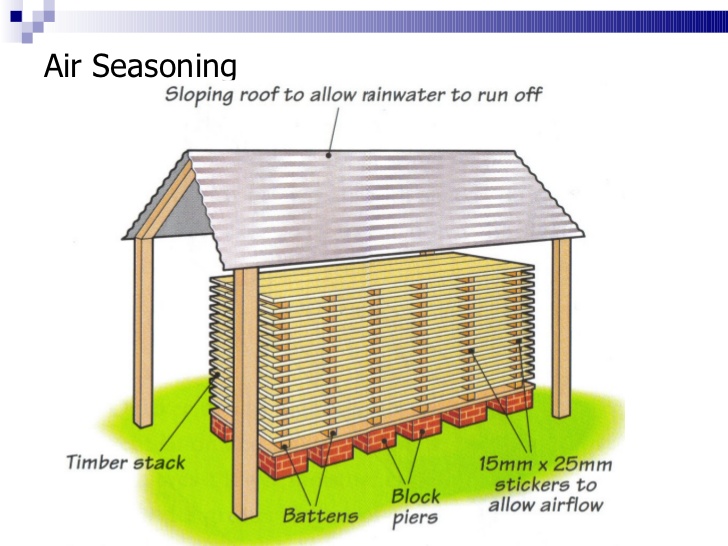

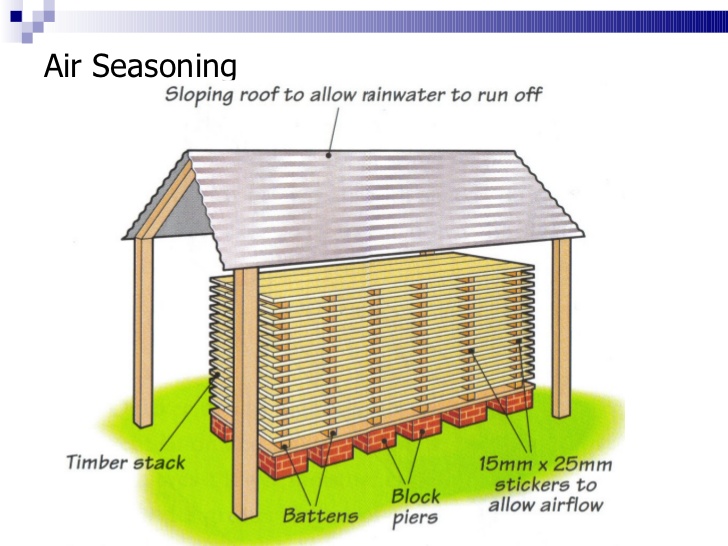

1. The Air seasoning( Natural Seasoning)

2. The Kiln Seasoning ( Artificial Seasoning)

1.

The Air Seasoning: This is also called Natural seasoning. This method of seasoning wood involves stacking the wood in the open shed for a long period of time and allows it to dry naturally. The stacked planks (wood) are arranged on top of one another with pieces of small wood called stackers in between them in order to allow the free circulation of air.

Advantages:

It is relatively cheap.

It requires little attention

Disadvantages:

The rate of drying is slow, so it takes a very long time to be seasoned.

There is no control over the drying process.

2.

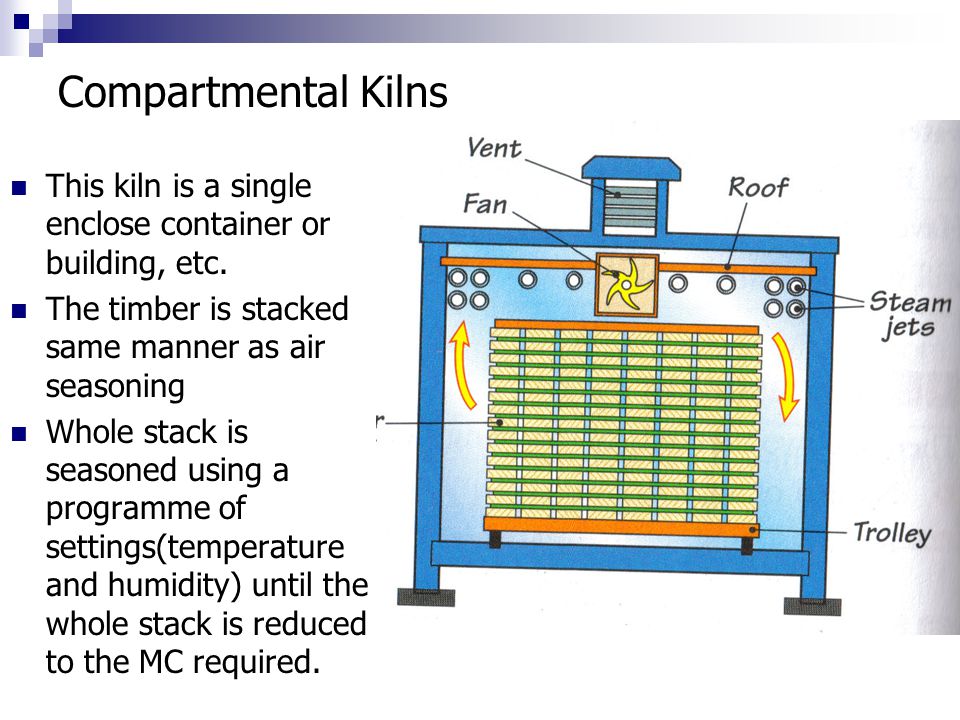

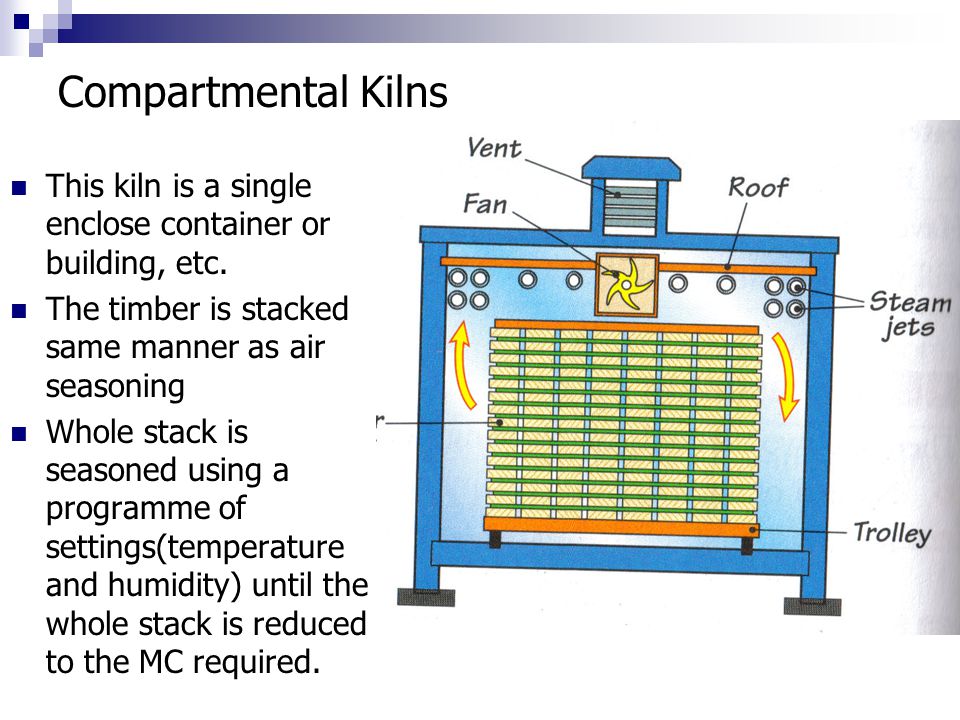

The Kiln Seasoning: This method of seasoning wood, involves stacking the timber in a specially heated chamber. The planks are stacked in the same way as in the air seasoning, but the planks are placed in a specially heated chamber called kiln. In this process, the rate of drying planks is faster than air seasoning method.

REASONS FOR SEASONING WOOD

REASONS FOR SEASONING WOOD

1. It makes the wood become lighter in weight.

2. It makes the wood become more stable.

3. It makes the wood to take paints, polishes and preservatives easily.

4. It makes the wood to be durable i.e. last longer

5. It reduces the attack of fungi and insects on wood.

6. It reduces the moisture content of the wood.

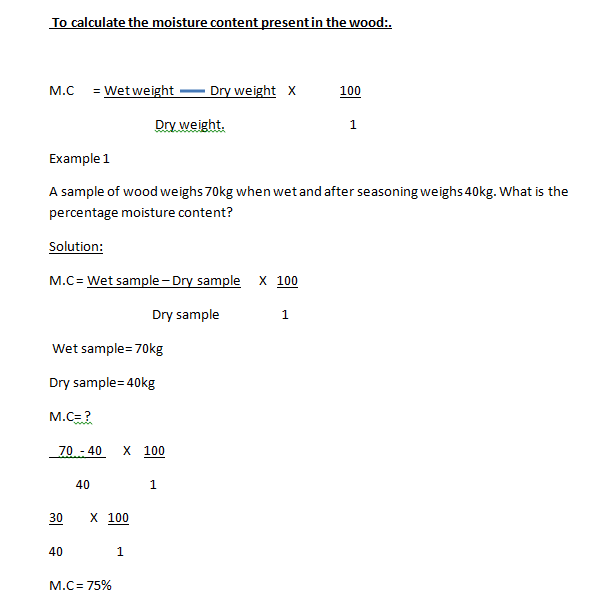

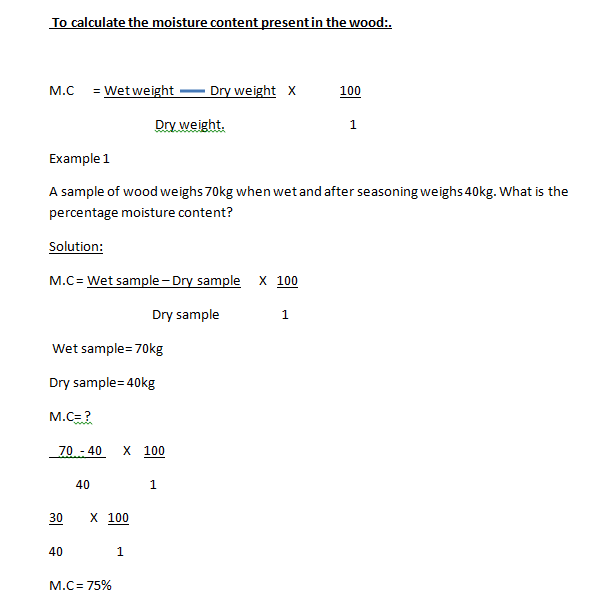

To calculate the moisture content present in the wood:.

Class work.

1. The weight of sample of wood before drying was found to be 120kg. The percentage moisture content was found to be 50%, what is the weight of the sample of the wood after drying?

Answer= 80kg.

2. The weight of a sample of wood after drying was found to be 60kg. The percentage moisture content was 40%, what is the weight of the wood before drying?

Answer= 84kg.

LESSON 3

Common Timber Defects

Defects in timber

A defect in timber is any feature in timber that reduces the quality and the market value of the timber.

Types of defects in timber.

Defects in timber can be grouped into two types:

I. The Natural defects

II. The Artificial defects.

THE NATURAL DEFECTS:

The Natural defects in timber are those defects that are caused by natural occurrences such as thunder, rain, growth circumstances etc. Examples of natural defects are:

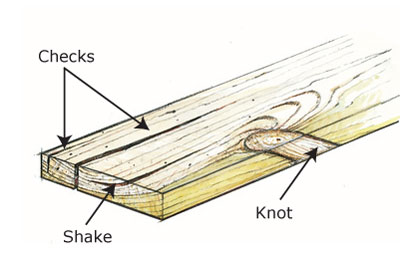

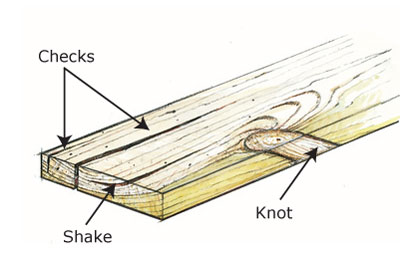

Shakes :

Shakes : These are disruptions in the wood fibre which show up as splits and separation of parts of the stem of a tree.

Examples:

Heart shakes: This is visible on the cross-section of the centre of the log, extending along the rays

Star Shakes: This is similar to the heart shake, but with more spilts like star.

Cup Shakes: These are visible cracks which go round the growth ring of the wood.

Ring Shakes: These are circular cracks on the timber.

Knot: knots are caused by branches.

https://www.slideshare.net/RajatYadav18 ... nd-defects

THE ARTIFICIAL DEFECTS:

https://www.slideshare.net/RajatYadav18 ... nd-defects

THE ARTIFICIAL DEFECTS:

The artificial defects are those defects that are caused by human beings through careless handling of the wood while processing.

Examples :

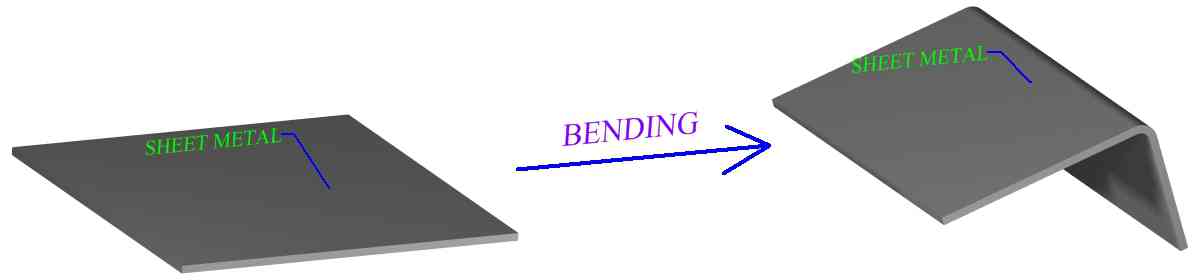

Cup: This is the concave curvature across the face of the timber.

Bow: This is either concave or convex curvature along the length of the plank.

Check: This is the separation of the wood along the grains of the wood.

Twist: This is the spiral form of distortion along the length of the plank.

Insect Attack: This is the visible minute holes seen on the surface of the wood. The insects always attack sap wood.

Warps: The warp in timber is called twists. They are caused by improper seasoning procedures of wood fibers.

https://www.slideshare.net/MrWoodwork/13-diseases

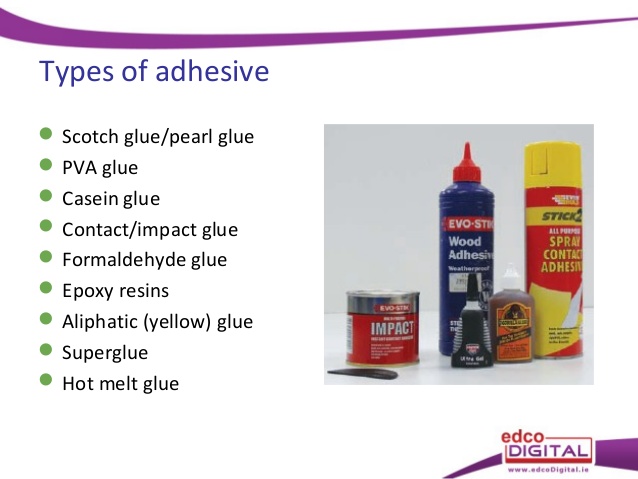

Wood preservation.

This is the process of prolonging the life span of wood by the application of wood preservatives.

Wood preservatives are applied to the planks to prevent insect and fungal attack.

Wood Preservatives: These are the chemicals used to poison the destructive agents in the wood. E.g. fungi, insects, and termites. Some of the chemicals used as the wood preservatives are solignum, creosote, phenols, paints etc.

Types of wood preservatives: There are three major types of wood preservatives depending on the method of mixing.

1. Water soluble preservatives: These are the chemicals that can be mixed thoroughly with water only.

2. Oils soluble preservatives: These are the chemicals that can be mixed thoroughly with oils only.

3. Solvent soluble preservatives: These are the chemicals that can be mixed thoroughly with evaporating liquids only.

Methods of Applying the Preservatives:

The methods of applying good preservatives to dry wood are:

i.

Brushing Method: This is the process of using brush to apply preservatives to the wood.

ii.

Spraying Method: This is the process of using spraying gun to apply preservatives to the wood.

iii.

Cold Immersion Method: This is the method of immersing (dipping) planks in an unheated solution of preservatives for one or two days.

iv.

Open Tank Method (Hot and Cold Method): This is the process in which the plank is immersed in a tank containing hot liquid preservatives. This process is normally used for Treating poles and fence posts.

v.

Pressure Treatment Method: This is process in which planks are placed inside an enclosed metal cylinder. In the process, the preservatives are being forced into the plank under high pressure. This enables the wood to be preserved either by pumping the solution into the entire cell cavity or by merely coating the cell wall with the preservatives and finally draining the cell cavity, leaving the cell saturated with preservatives, when the process is completed.

Properties of Good preservatives:

The following are the properties of good preservatives:

I. It must be poisonous to the destructive agents.

II. It must be safe to handle

III. It must be permanent to the wood on application

IV. It must be easy to apply on the wood

V. It must be chemically stable for a long time on application to the wood.

LESSON 4

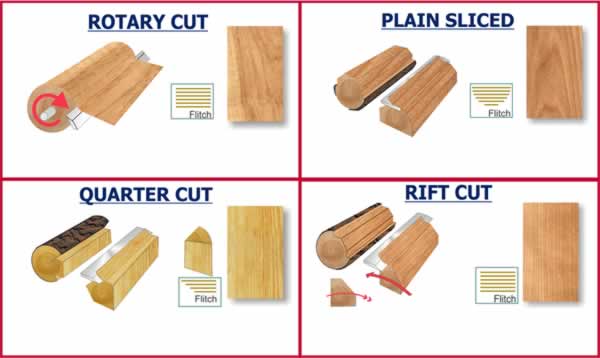

Veneer

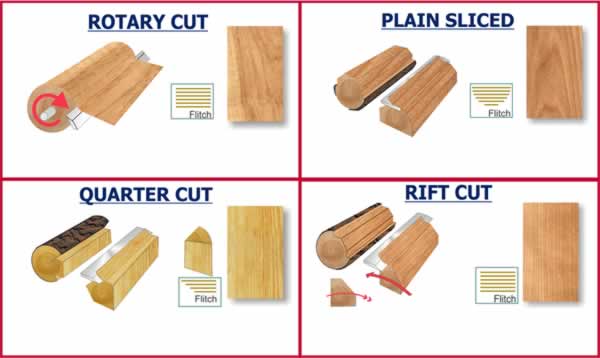

Veneers : A veneer is a thin layer of sliced sheet obtained from wood. The thickness of the veneers ranges from 0.5mm – 3.0mm

Method of making veneers

1. Rotary method

2. Slicing method

3. Eccentric method

1.

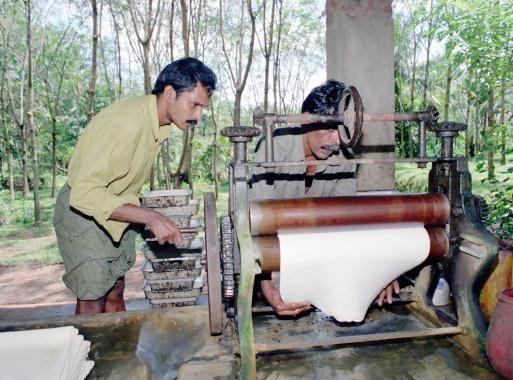

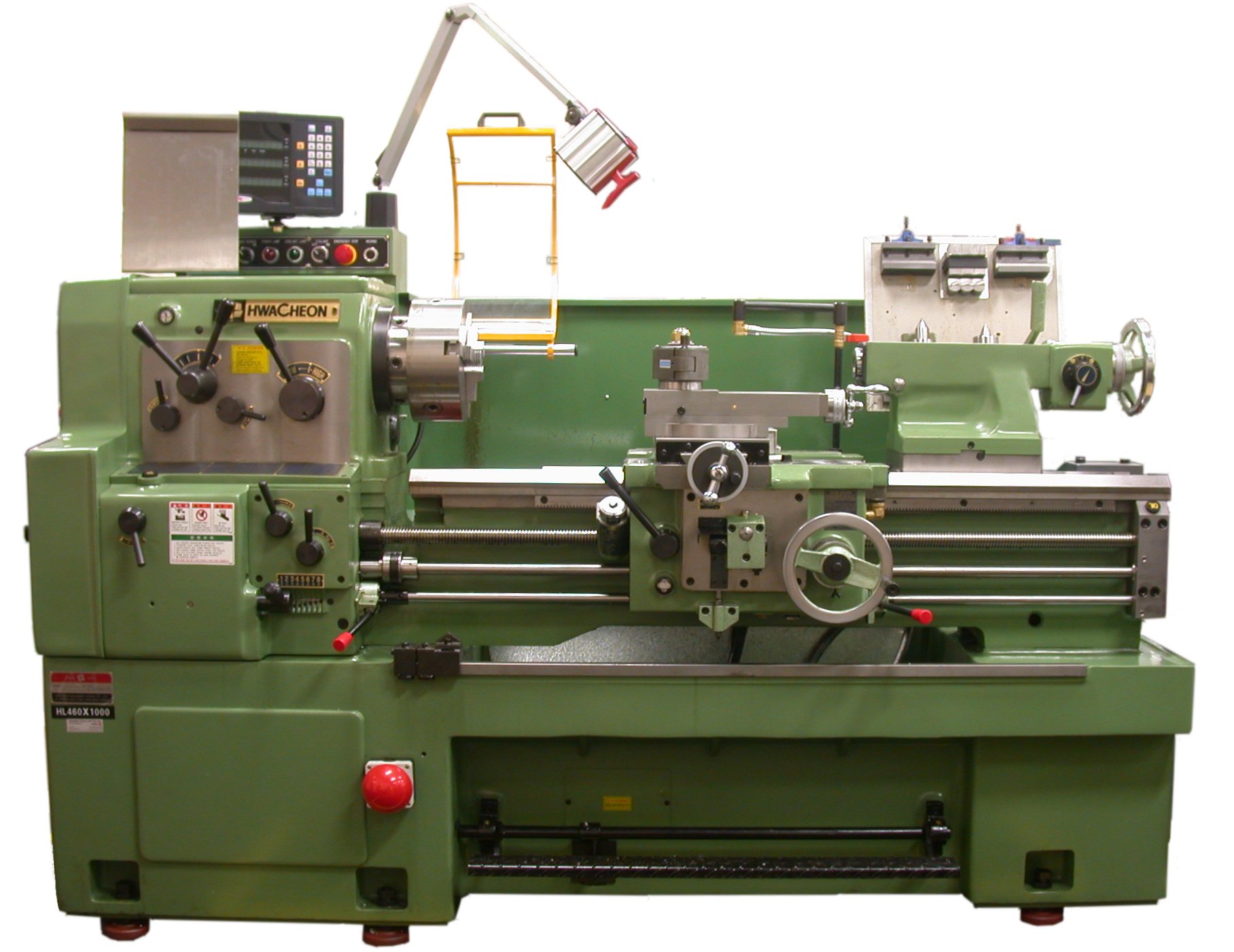

Rotary Method. The rotary method requires the wood to be steamed in other to loosen the fiber and make it easy to peel with knives attached to the lathe machine. With the lathe machine, large sheets of veneers can be produced and cut to marked sizes for commercial purposes.

2.

Slicing Method. The timber is safely attached to the slicing machine. The knife or the cutting blade on the machine will be set on the wood depending on the thickness of the veneer required. The thickness is set after every stroke. On switching on the machine, it slices the sheet of wood to the required thickness depending on the purpose of the veneer.

3.

Eccentric Peeling. In eccentric peeling method the log of wood is first cut into four parts each of which is called quarter log. Each log is placed on the lathe machine with the sapwood at the centre. The peeling of the veneer commences from the heartwood to the sapwood.

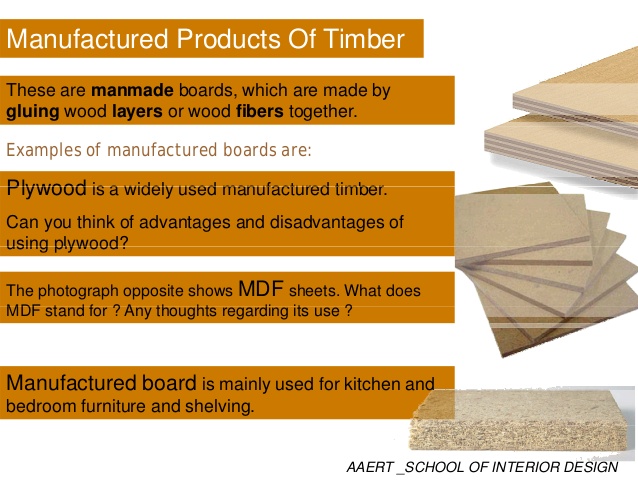

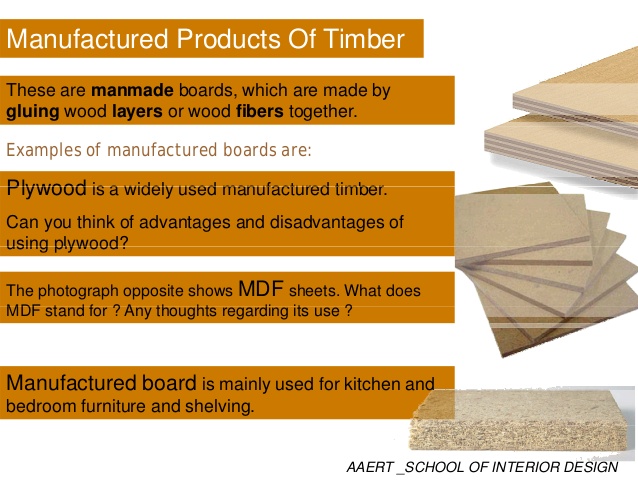

Types and Manufacture of Laminated Boards.

Laminated boards are man-made boards manufactured by man from veneers, wood waste, synthetic and impregnated paper bonds. Types and methods of manufacture of laminated boards are as follows;

1. Examples of Man-made boards.

I. Plywood

II. Particle board

III. Laminated board

IV. Chip board

V. Composite board

VI. Pattern board

VII. Block boards

1.

Ply wood

Plywood is produced by bonding three or more veneers together with strong glue. The grain of each sheet of veneer is laid at right angle to each other. After successfully bonding the sheets of veneers together, they are cut in different sizes for commercial purposes such as 2440mm X 1220mm with thickness, ranging from 1 to 25mm.

2.

Chipboards. Chipboards are produced with wood chips. The chips which are wastes from wood are mixed with glue. After mixing thoroughly with glue they are pressed together and heated to form boards. The boards can be veneered to form smooth surfaces. Chipboards can be used in the construction of kitchen cabinets.

3.

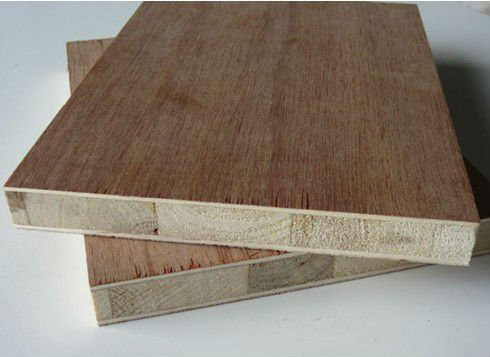

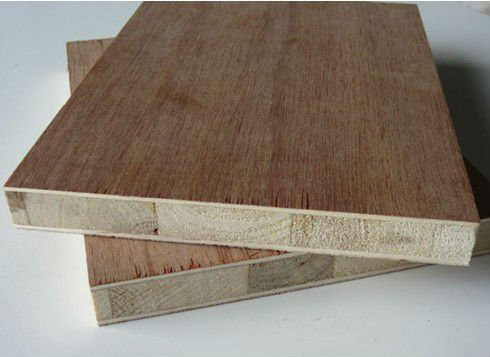

Blockboards. Blockboards are made of strips of wood placed side by side and covered with veneers. It is similar to plywood. But it is thicker, stronger and cannot be bent easily. They can be used in the construction of different types of cabinets including tables, cupboards and room dividers.

4.

Hardboards :They are manufactured from waste wood mixed and mashed with hardeners and bonding materials like glue. After mixing with glue or any other bonding material they are pressed with great pressure and high temperature. Hardboards can be faced with veneer, enamel and plastics.

5.

Laminated Plastics: They are manufactured from synthetic resin and impregnated paper. The materials are bonded together with great pressure and heat is applied. Laminated plastics do not allow the passage of water through them. They are strong and durable.

ADVANTAGES OF MANUFACTURED BOARDS.

ADVANTAGES OF MANUFACTURED BOARDS.

Manufactured boards have the following advantages over solid wood.

i. They are available in flat large sheets.

ii. They can be cut easily and worked on.

iii. They can be easily nailed without splitting.

iv. They can be bent to form curves.

v. They do not check or warp like solid wood.

EVALUATION:

1) What is conversion of timber?

2) Mention three methods of conversion of timber.

3) Define seasoning.

4) Give three advantages of seasoning.

5) Mention five defects in timber.

6) List five properties of good wood preservatives.

ASSIGNMENT:

1. Draw a growing tree and label its parts.

2. State the function of each part labeled in (1) above.

3. Give three advantages of manufactured boards over solid wood.

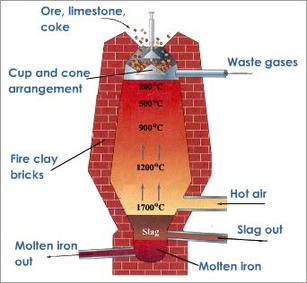

4. Read your textbook ‘ Basic Technology for Junior Secondary School’, By P.O Olawehinmi. Pgs 134-136 Study the topic ‘Production of Metallic Materials’ against the next lesson.