SCHEME OF WORK

WEEK TOPIC

1. Revision of last year work

2. Career Prospects and Opportunities in Technology: (a) Technology related careers; Mechanical, Electrical/Electronics, Civil, Building, Production, Automobile, Computer and Chemical Engineering, etc. (b) Employment Prospects.

3. Production of Materials- (a) Wood.(i) Timber growth, felling, conversion and seasoning, (ii)Properties of good timber preservatives. (iii)Common timber defects; twist, bowing, cupping, etc (iv)Methods of cutting veneers,(v)Types of Manufactured boards –plywood, chip board, block board, etc

4. Production of Materials (b) Metals (i)Production of metals; smelting, casting, etc. (ii)Carbon properties of steels, (iii)Metal alloys(c) Clay, Ceramics and Glass.(i)Methods of making clay(ii)Stages in producing Ceramics and Glass materials; shaping, blowing, firing etc.

5. Production of Materials- (d) Plastics and Rubber: (i)Methods of production plastics; injection moulding, calendaring, etc (ii)Methods of producing rubber materials; natural and synthetic

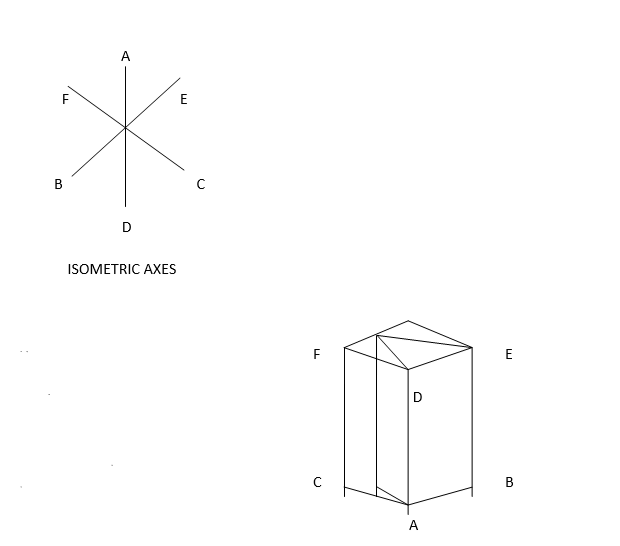

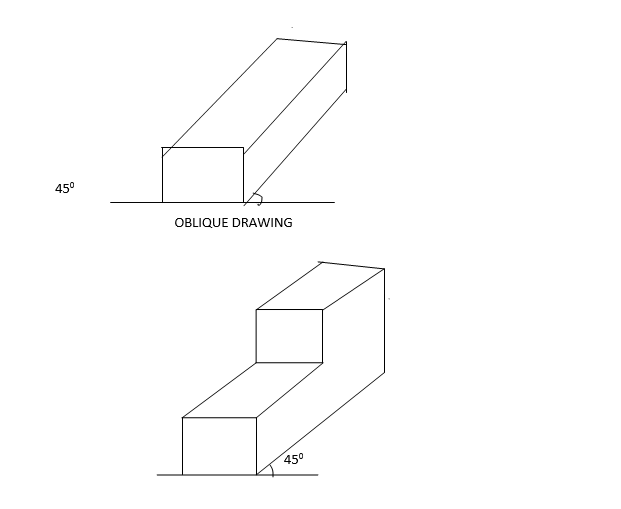

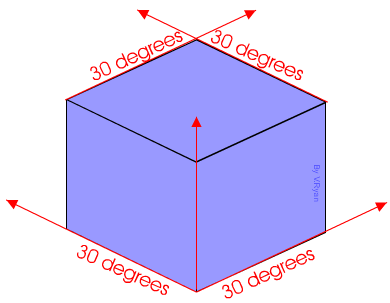

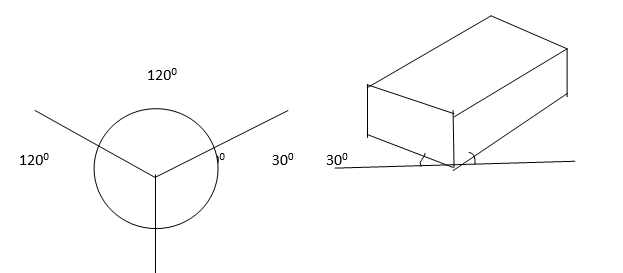

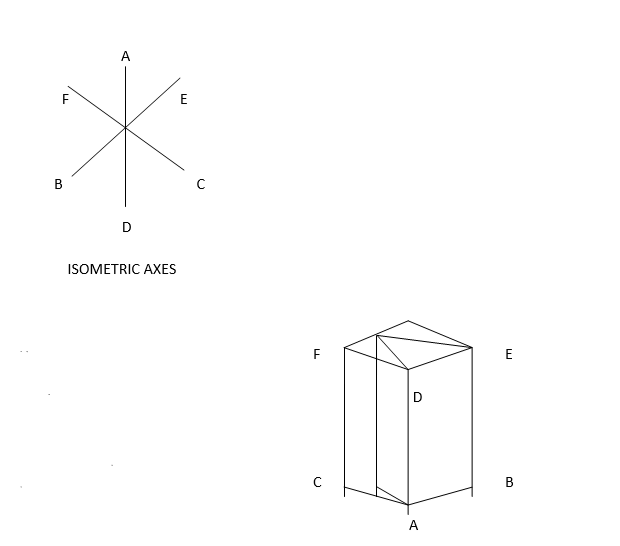

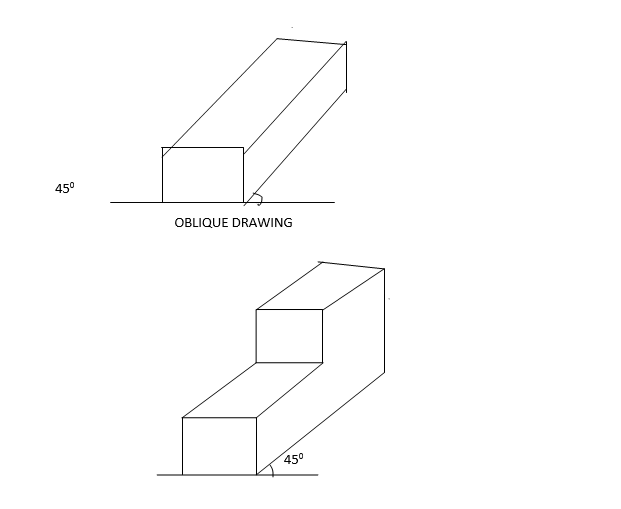

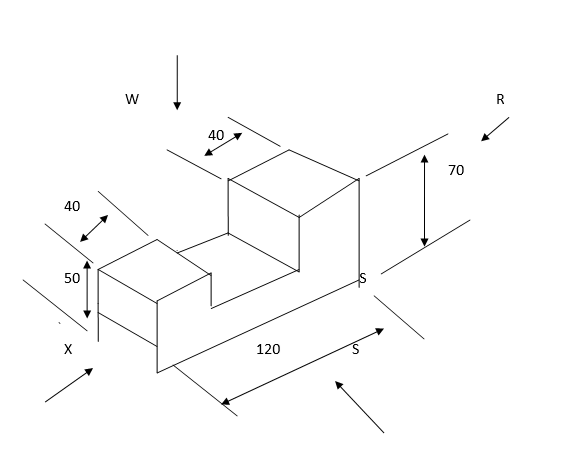

6. Drawing Practice –(a) Isometric and Oblique Drawings: (i)Isometric drawing; definition and axes, Isometric drawing of simple shaped blocks without curves. (ii)Oblique drawing- definition, oblique drawing

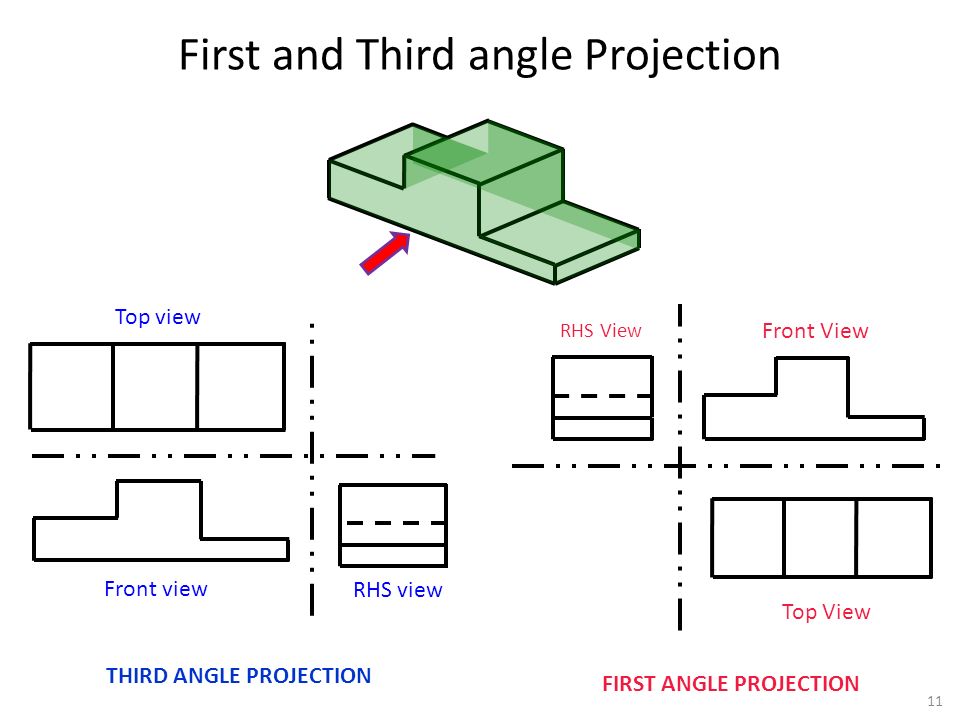

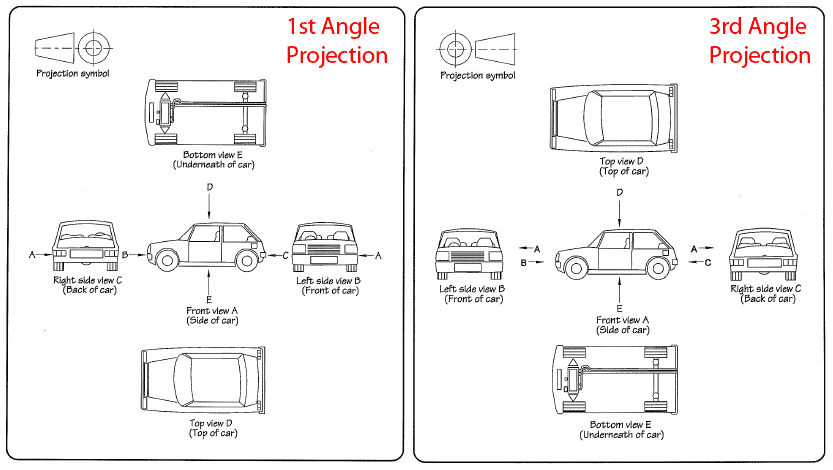

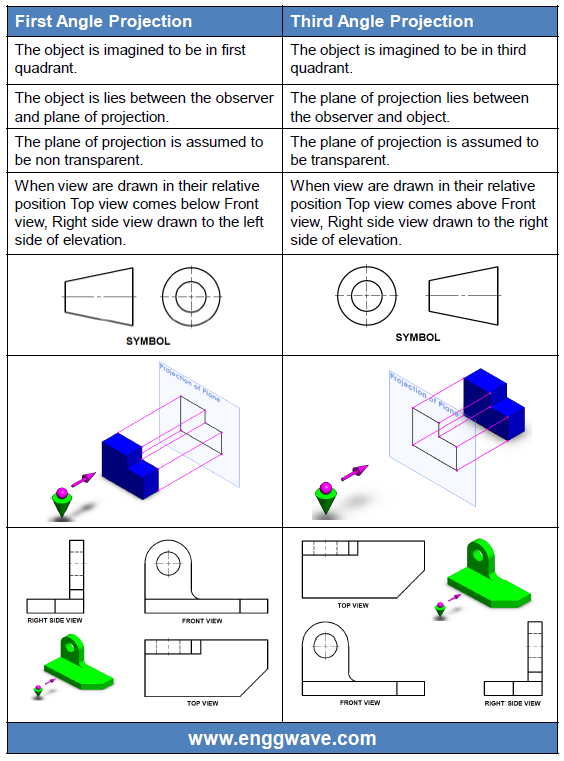

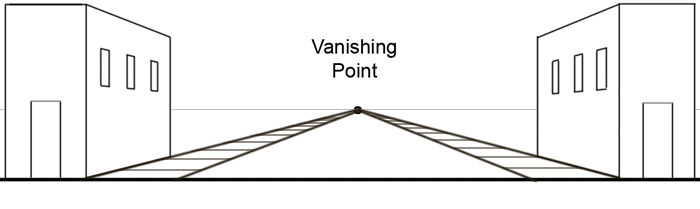

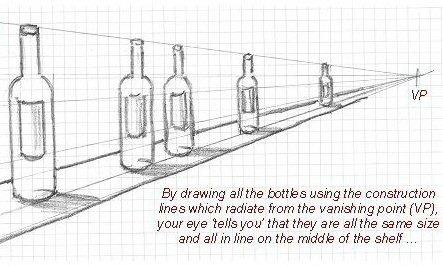

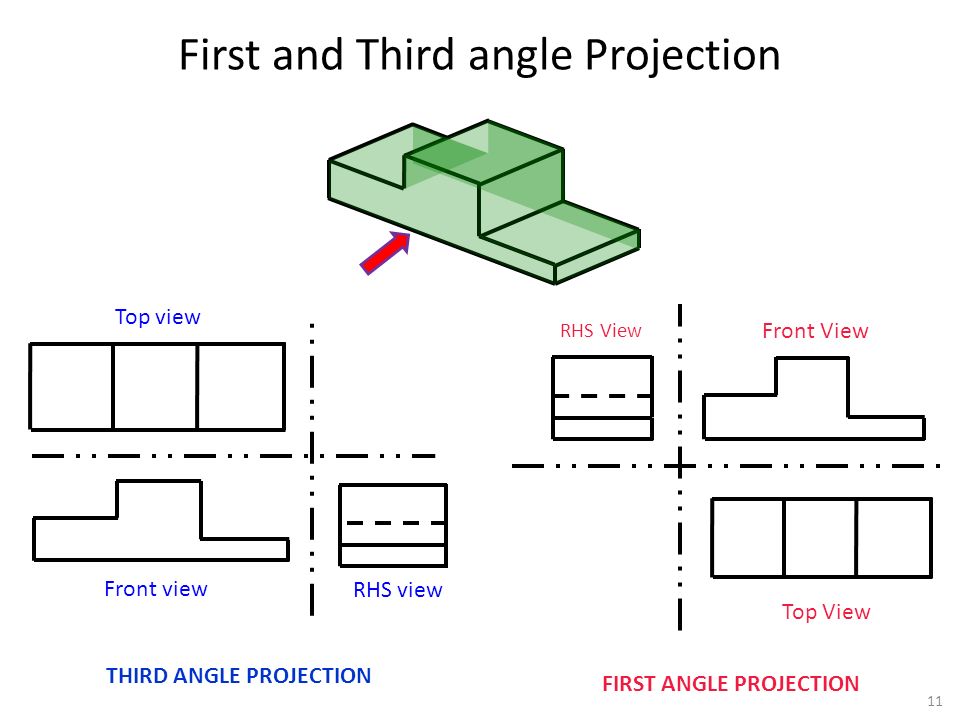

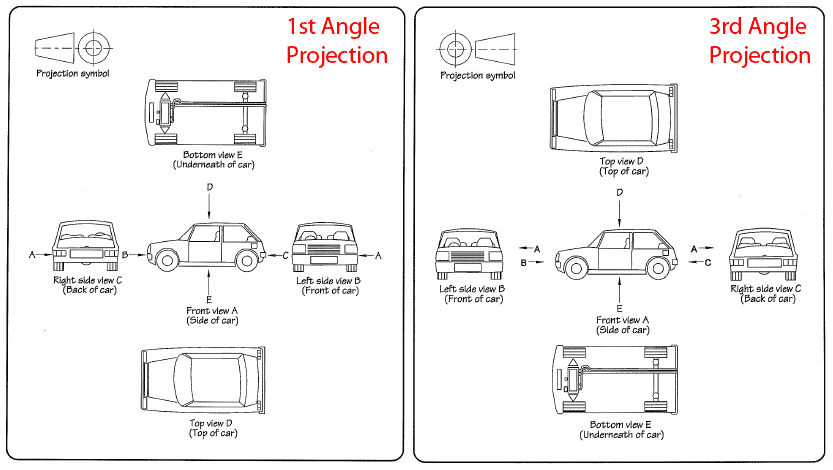

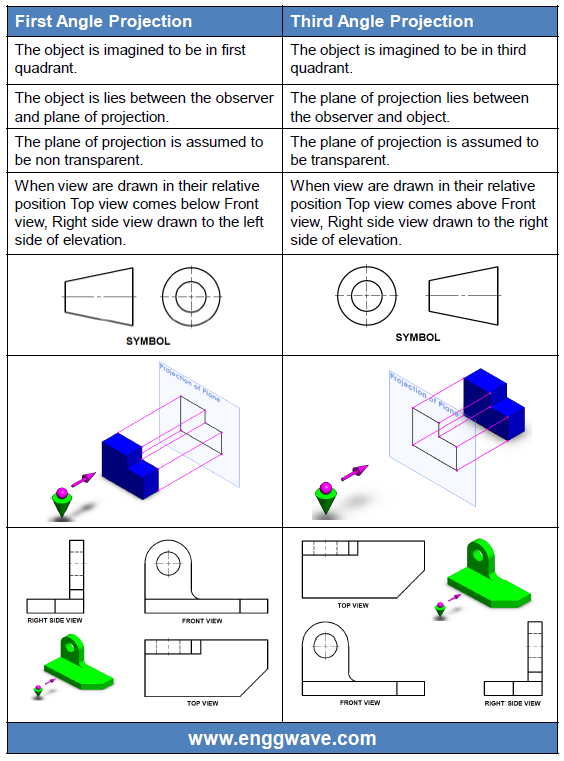

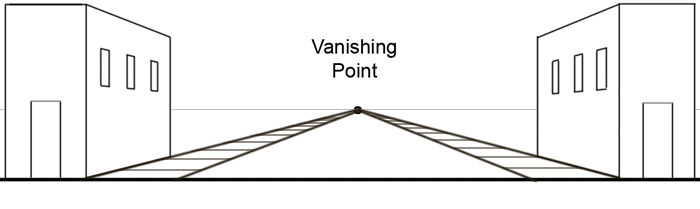

7. Drawing Practice- (c) orthographic Projection and (d) One-point Perspective Drawing (c) Orthographic Projection:- (i) Principal planes- vertical and horizontal. (ii) Angles of projection- First angle and Third angle. (iii) Principal views- front, side, plan. (iv)Placing principal views in the quadrants. (v) Dimensioning techniques. (d) One- point Perspective Drawing: (i) definition (ii) principles (iii) practice.

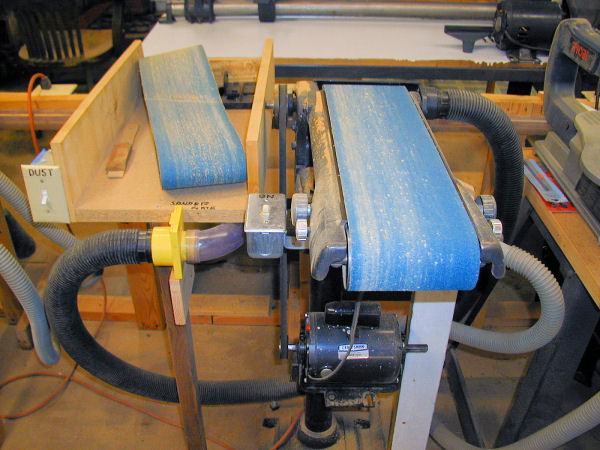

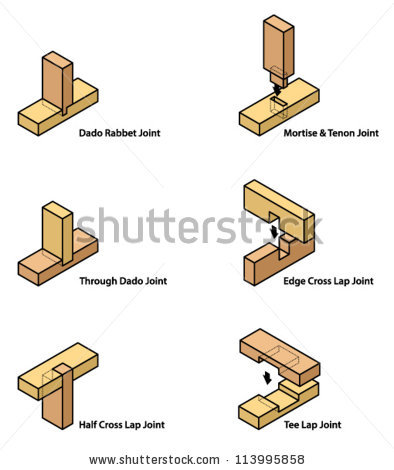

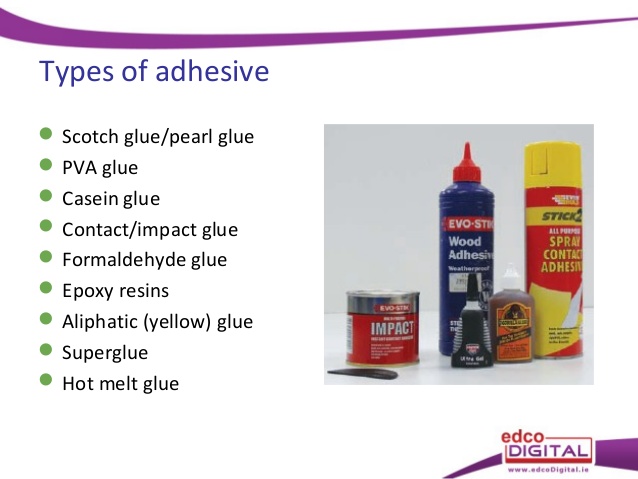

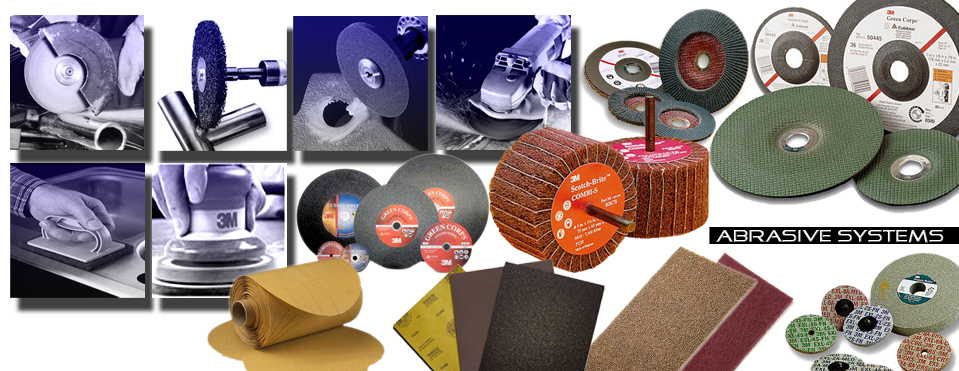

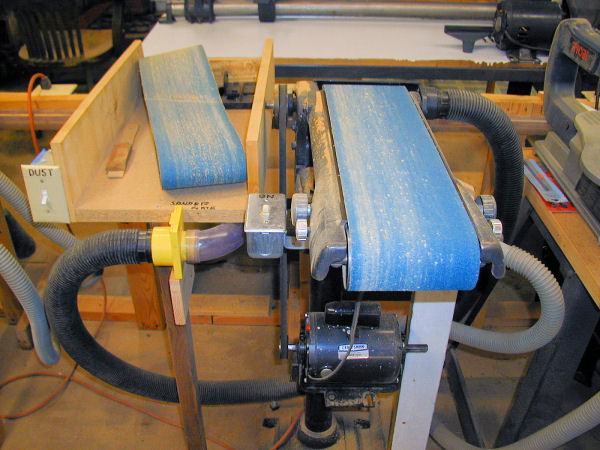

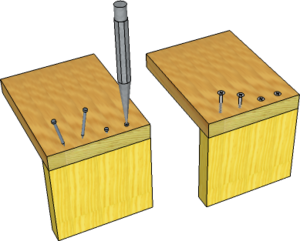

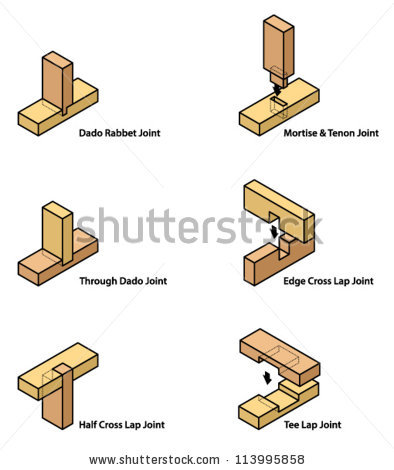

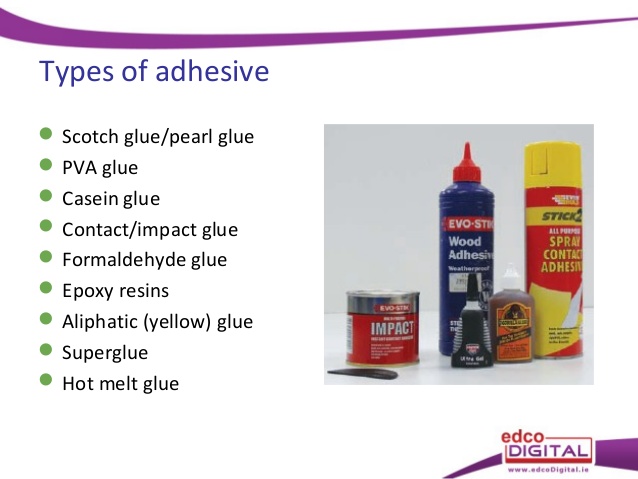

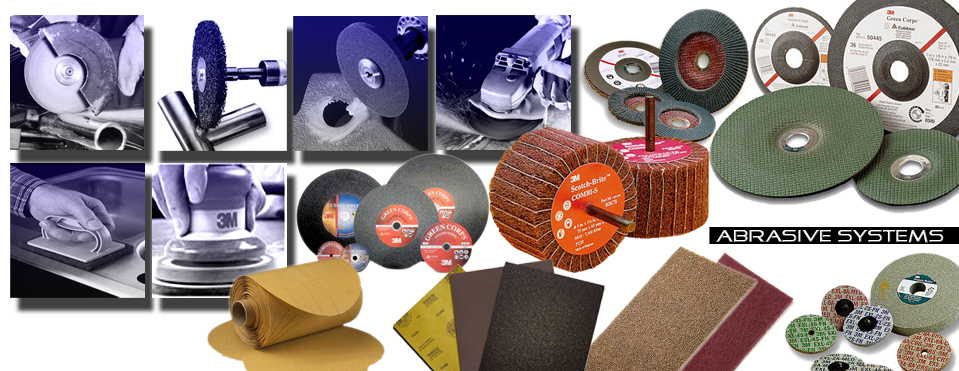

8. Tools and Machines – (a) Woodwork Machines and (b) Simple woodwork Projects:(a) Woodwork: (i) Portable power tools; belt sander, hand drill, fret saw, etc. (ii) Machine; circular, hand saw, wood lathe, surface planer, thicknesser, sanders, drill, etc. (b) Simple woodwork Projects: (i) Common joints: butt, bridle, mortice and tenon. (ii) Classification: framing, widening, etc. (iii) Uses: tables, boxes, etc. (iv) Woodwork projects: boxes, photo frame. (v) Non-wood materials, adhesives, abrasives, hinges.

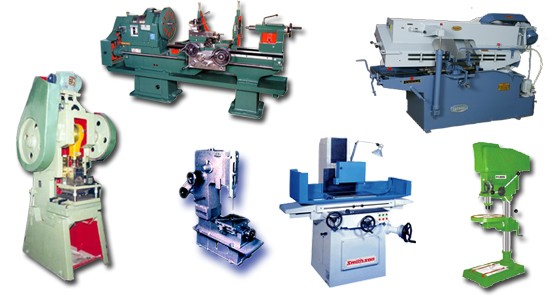

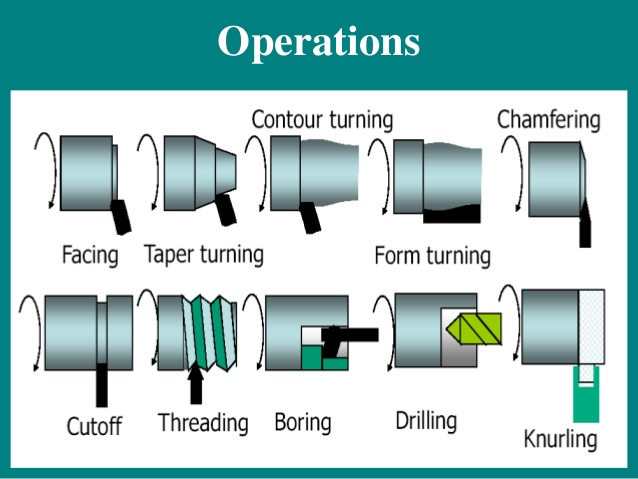

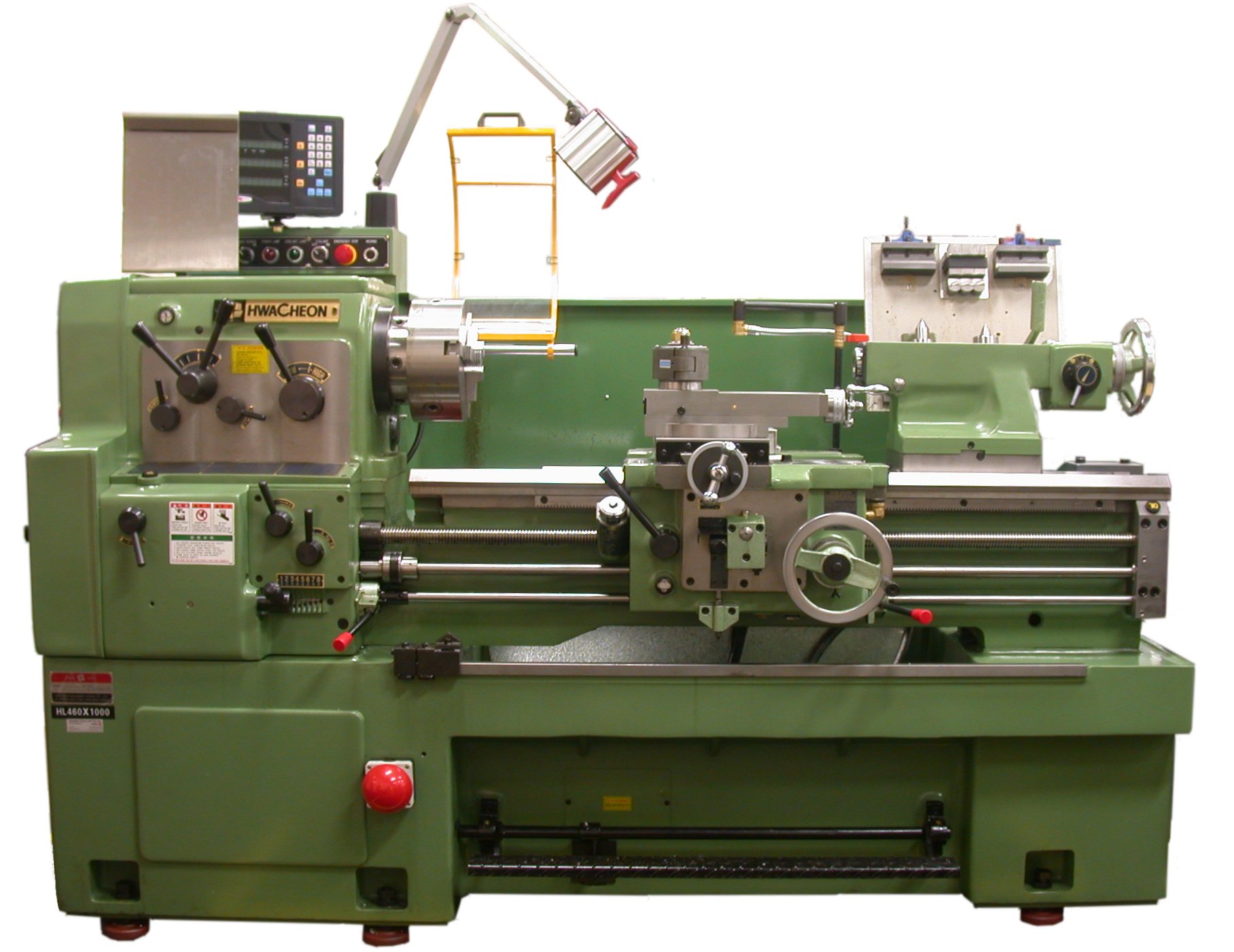

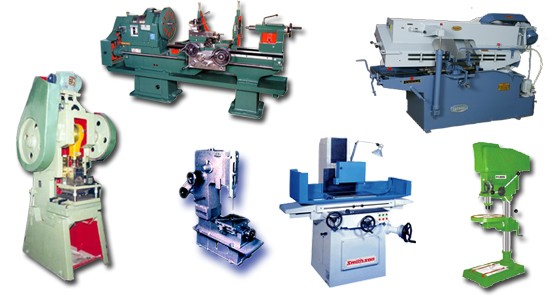

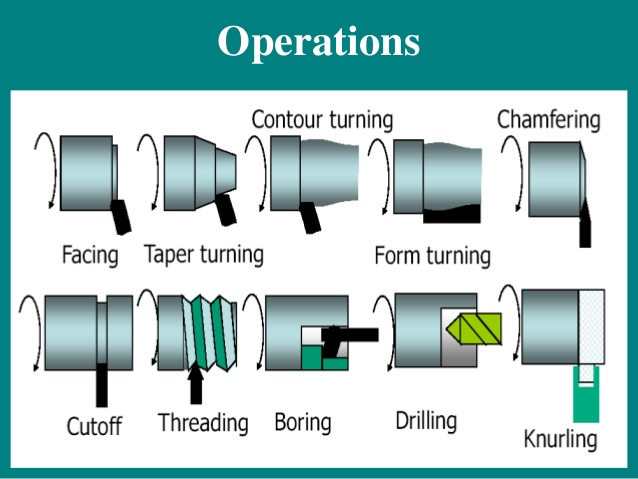

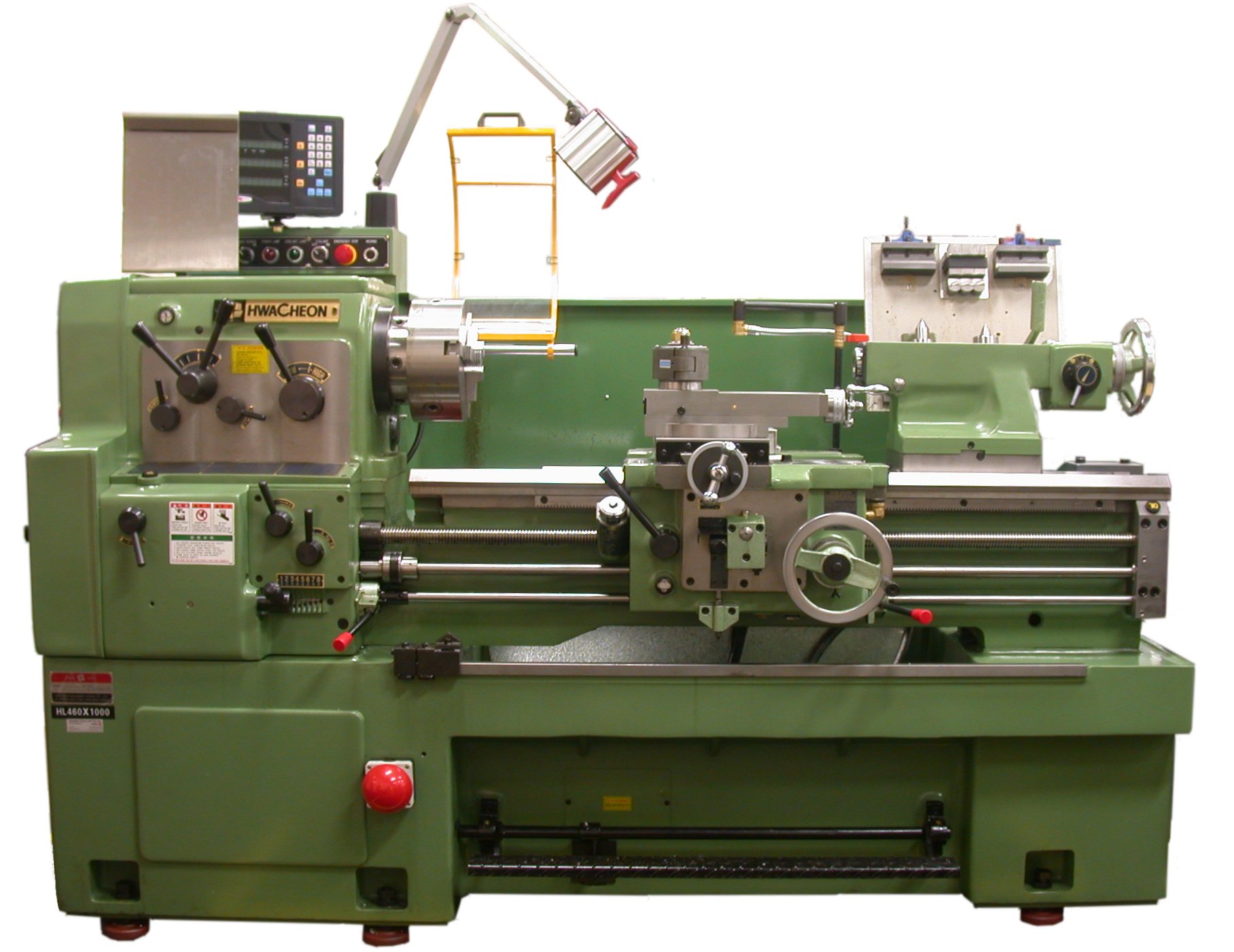

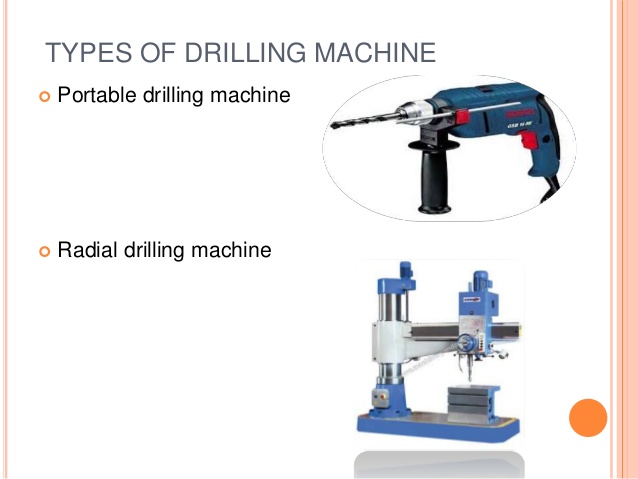

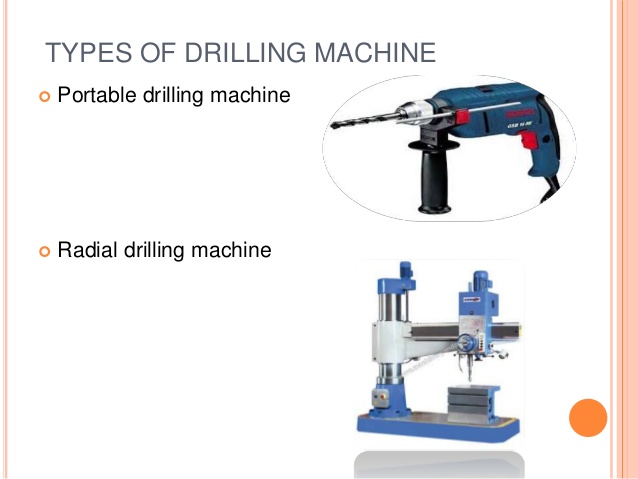

9. Tools and Processing- (a) Metalwork Machines: (i) Types of metalwork machines and their functions- cutting, turning, shaping, drilling, milling, grinding, etc. (ii) The centre lathe and its operation.

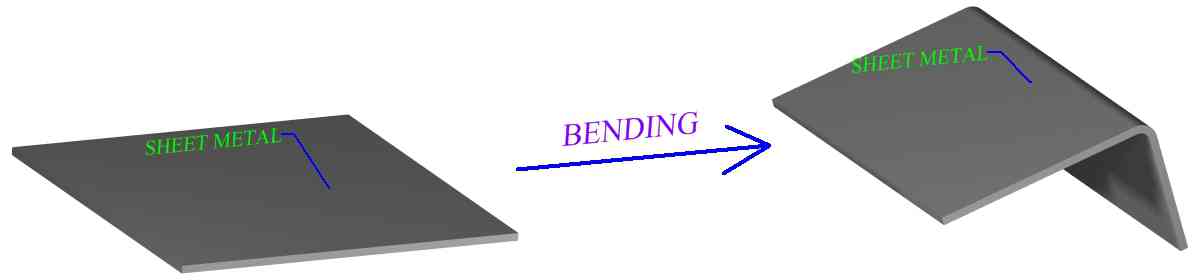

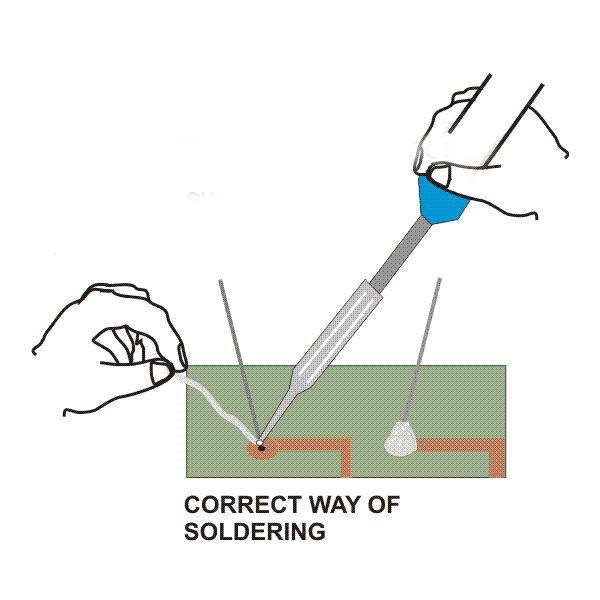

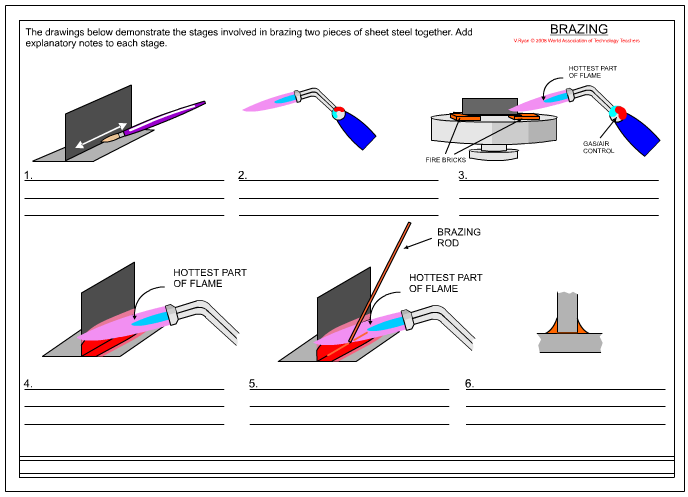

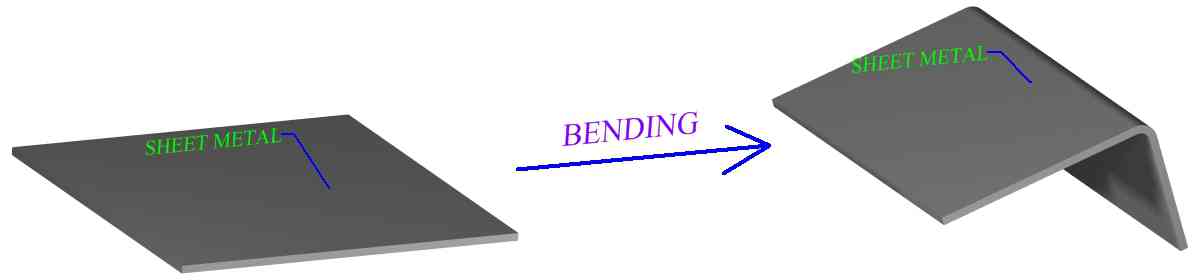

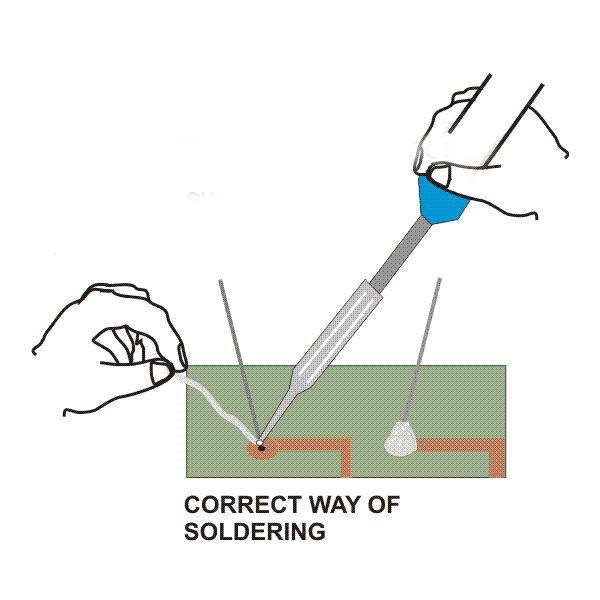

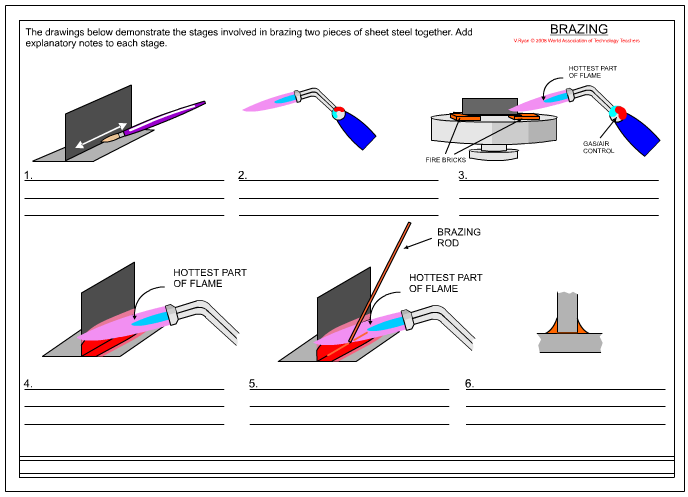

10. Tools and Processing- (b) Simple Metal work Projects: (i) Principles of measurement and measuring. (ii) Tools and cutting. (iii) Files and filing. (iv) Drills and drilling. (v) Bending and folding. (c) Soldering and Brazing: (i) Definition of soldering and brazing. (ii) Metal joining; soft soldering and hard soldering.

11. Revision.

Basic Textbooks

1. Basic Technology for Junior Secondary Schools or JS 3 (UBE Edition); By P.O Olawehinmi

2. NERDC Basic Technology for Junior Secondary Schools UBE Edition.

1ST TERM

WEEK 1

LESSON 1

TOPIC: CAREER PROSPECTS AND OPPORTUNITIES IN TECHNOLOGY.

CONTENT:

1. Technology related careers.

2. Employment prospects.

What is the Technology related career?

A career is a professional related job from which one earns his or her living in one’s adult life, which he/ she chooses and becomes engaged in it. The longer you stay in a particular career (job) the more competent and grounded you become in it.

Career Education is education which consists of those activities and experiences through which an individual learns of work.

Vocation is one’s primary work role at any given time.

Occupation is one’s primary work role in the world of paid employment.

Any career which involves the use of

I. Application of scientific principle

II. Conversion of material

III. Tools and machine are related to technology career, because they train students in the use of simple tools and therefore make the students to be useful in such professional jobs as installation and maintenance of parts of machine and structure etc. The course of study at the tertiary institution level, for the technology related careers are basically Engineering course.

These career courses include:

1. Agricultural Engineering

2. Aeronautical Engineering

3. Mechanical Engineering

4. Civil Engineering

5. Electrical Engineering

6. Computer Engineering

7. Chemical Engineering

8. Food Engineering

9. Mining Engineering

10. Metallurgical Engineering

1. Agricultural Engineering: This is the profession which focuses on the solution to the engineering problems of Agriculture. The agricultural engineering incorporates research and activities regarding the way farm wastes could be converted into more useful forms such as supply energy.

2. Aeronautical Engineering: This is the profession which concerned with the development, design, construction, uses and maintenance of aircraft of various kinds as well as the system which are used for their effective operation. Such aircrafts include airplane, helicopter, space shuttle, jet etc.

3. Mechanical Engineering: This is the profession which is concerned with the design, construction, operation and maintenance of machines and mechanical systems of various kinds. The major divisions of mechanical engineering are:

I. Production Engineering or Industrial Engineering: This is concerned with the development and application of various kinds of goods in industries.

II. Auto mobile Engineering is concerned mainly with vehicles of various kinds

III. Refrigeration Engineering is concerned with the development, application and maintenance of cooling and freezing system of both domestic and industrial levels.

4. Civil Engineering: This is the profession which is concerned with the design, construction, application, operation and maintenance of structure. The major divisions of civil Engineering are:

5. Building Engineering: This is concerned with building and structures for human habitation and activities involved in the production of shelter for other human interests.

6. High way Engineering: This concerns itself with the building of roads, land and water bridges as well as super high ways

7. Water resources Engineering: This is concerned with the design and construction of bore holes, canals, dams, Dredging works, and so forth.

8. Transportation Engineering: This is concerned with the integration of roads, rails and water transportation system for moving people and goods for the good of the society.

9. Electrical Engineering: The Electrical Engineering can be grouped into two broad areas:

I. Heavy current engineering: This is concerned with the design, construction, application and maintenance of transmitting, utilizing and distributing electricity for various uses. It also concerns itself with the application of electrical appliances such as transformer, electric motors, switches, generators, and conductors.

II. Electronics Engineering: This is concerned with the method through which electricity can be made for a more productive service and control the flow of electric current (electrons) in the internal circuit of Radio, Television DVD, and CD player and so forth. It also involves the development and application of telecommunication system, such as the design and construction of computers, calculator and so forth.

10. Computer Engineering: This is the profession which is concerned with the development, application and maintenance, installation of various forms of computer hard wares and the software. The hard ware aspect involves the development of computer accessories, integrated circuits (I.C)

11. Chemical Engineering: This is the profession which is concerned with the design, construction, installation, operation and maintenance of equipment and plant through which chemical substance can be handled and converted into useful forms. The related fields of chemical Engineering are:

I. Material Engineering: This is concerned with various useful materials such as paper, glass, silicon, plastic and so forth.

II. Nuclear Engineering: This is concerned with safe handling and the use of nuclear materials

III. Petrol Chemical Engineering: This is concerned with the maintenance, processing and uses of materials of petroleum origin.

12. Food Engineering: This is the profession which is concerned with the Development of food stuffs. It is concerned with industrial production of food and drinks on a large scale.

13. Mining Engineering: This is the profession which is concerned with the development of coal and other materials of fossil origin and precious stones.

14. Metallurgical Engineering: This is the profession which is concerned with ferrous and non-ferrous metals. It focuses on the way of finding the best methods for sourcing these materials as well as the best process for purifying them.

Employment Prospects.

Career Choice

The subject requirements for entry into these technology related career opportunities include;

1) English language

2) Mathematics

3) Physics

4) Chemistry

5) Biology

6) Geography

7) Technical Drawing.

To make a good career choice the following variables are necessary:

Subject combinations that is compulsory for your choice of career

Interest in the career and in the subjects related to the chosen career is necessary.

Knowledge of the work involved in the chosen career.

Academic achievement in the subjects required for the chosen career.

Difficulties perceived in the subjects required for the chosen career.

Motive for choosing the career.

Periods of Occupational choice.

1) Fantasy Period

2) Tentative Period

3) Realistic Period

EMPLOYMENT OPPORTUNITIES IN TECHNOLOGY

1. Employment in Industrial sector

2. Employment in Telecommunication sector

3. Employment in Educational sector

4. Employment in the service sector

5. Employment in Utilities

6. Employment in Consultancy sector

7. Employment in Construction sector

8. Employment in petroleum sector

9. Employment in farming and food processing sector.

EVALUATION:

I. What is a career?

II. Explain why it is necessary for someone to choose a career.

III. Mention eight job opportunities for technological engineers in a developing country like Nigeria.

ASSIGNMENT: Read New Basic Technology for Junior Secondary School, Bk 3, By P. O Olawehinmi. Pg 128 – 132 and answer the following questions:

a. State two areas where trees are found.

b. List five uses of wood at home.

c. Mention four stages a log of wood must pass through before it becomes workable and useful.

TOPIC: CAREER PROSPECTS AND OPPORTUNITIES IN TECHNOLOGY.

CONTENT:

1. Technology related careers.

2. Employment prospects.

What is the Technology related career?

A career is a professional related job from which one earns his or her living in one’s adult life, which he/ she chooses and becomes engaged in it. The longer you stay in a particular career (job) the more competent and grounded you become in it.

Career Education is education which consists of those activities and experiences through which an individual learns of work.

Vocation is one’s primary work role at any given time.

Occupation is one’s primary work role in the world of paid employment.

Any career which involves the use of

I. Application of scientific principle

II. Conversion of material

III. Tools and machine are related to technology career, because they train students in the use of simple tools and therefore make the students to be useful in such professional jobs as installation and maintenance of parts of machine and structure etc. The course of study at the tertiary institution level, for the technology related careers are basically Engineering course.

These career courses include:

1. Agricultural Engineering

2. Aeronautical Engineering

3. Mechanical Engineering

4. Civil Engineering

5. Electrical Engineering

6. Computer Engineering

7. Chemical Engineering

8. Food Engineering

9. Mining Engineering

10. Metallurgical Engineering

1. Agricultural Engineering: This is the profession which focuses on the solution to the engineering problems of Agriculture. The agricultural engineering incorporates research and activities regarding the way farm wastes could be converted into more useful forms such as supply energy.

2. Aeronautical Engineering: This is the profession which concerned with the development, design, construction, uses and maintenance of aircraft of various kinds as well as the system which are used for their effective operation. Such aircrafts include airplane, helicopter, space shuttle, jet etc.

3. Mechanical Engineering: This is the profession which is concerned with the design, construction, operation and maintenance of machines and mechanical systems of various kinds. The major divisions of mechanical engineering are:

I. Production Engineering or Industrial Engineering: This is concerned with the development and application of various kinds of goods in industries.

II. Auto mobile Engineering is concerned mainly with vehicles of various kinds

III. Refrigeration Engineering is concerned with the development, application and maintenance of cooling and freezing system of both domestic and industrial levels.

4. Civil Engineering: This is the profession which is concerned with the design, construction, application, operation and maintenance of structure. The major divisions of civil Engineering are:

5. Building Engineering: This is concerned with building and structures for human habitation and activities involved in the production of shelter for other human interests.

6. High way Engineering: This concerns itself with the building of roads, land and water bridges as well as super high ways

7. Water resources Engineering: This is concerned with the design and construction of bore holes, canals, dams, Dredging works, and so forth.

8. Transportation Engineering: This is concerned with the integration of roads, rails and water transportation system for moving people and goods for the good of the society.

9. Electrical Engineering: The Electrical Engineering can be grouped into two broad areas:

I. Heavy current engineering: This is concerned with the design, construction, application and maintenance of transmitting, utilizing and distributing electricity for various uses. It also concerns itself with the application of electrical appliances such as transformer, electric motors, switches, generators, and conductors.

II. Electronics Engineering: This is concerned with the method through which electricity can be made for a more productive service and control the flow of electric current (electrons) in the internal circuit of Radio, Television DVD, and CD player and so forth. It also involves the development and application of telecommunication system, such as the design and construction of computers, calculator and so forth.

10. Computer Engineering: This is the profession which is concerned with the development, application and maintenance, installation of various forms of computer hard wares and the software. The hard ware aspect involves the development of computer accessories, integrated circuits (I.C)

11. Chemical Engineering: This is the profession which is concerned with the design, construction, installation, operation and maintenance of equipment and plant through which chemical substance can be handled and converted into useful forms. The related fields of chemical Engineering are:

I. Material Engineering: This is concerned with various useful materials such as paper, glass, silicon, plastic and so forth.

II. Nuclear Engineering: This is concerned with safe handling and the use of nuclear materials

III. Petrol Chemical Engineering: This is concerned with the maintenance, processing and uses of materials of petroleum origin.

12. Food Engineering: This is the profession which is concerned with the Development of food stuffs. It is concerned with industrial production of food and drinks on a large scale.

13. Mining Engineering: This is the profession which is concerned with the development of coal and other materials of fossil origin and precious stones.

14. Metallurgical Engineering: This is the profession which is concerned with ferrous and non-ferrous metals. It focuses on the way of finding the best methods for sourcing these materials as well as the best process for purifying them.

Employment Prospects.

Career Choice

The subject requirements for entry into these technology related career opportunities include;

1) English language

2) Mathematics

3) Physics

4) Chemistry

5) Biology

6) Geography

7) Technical Drawing.

To make a good career choice the following variables are necessary:

Subject combinations that is compulsory for your choice of career

Interest in the career and in the subjects related to the chosen career is necessary.

Knowledge of the work involved in the chosen career.

Academic achievement in the subjects required for the chosen career.

Difficulties perceived in the subjects required for the chosen career.

Motive for choosing the career.

Periods of Occupational choice.

1) Fantasy Period

2) Tentative Period

3) Realistic Period

EMPLOYMENT OPPORTUNITIES IN TECHNOLOGY

1. Employment in Industrial sector

2. Employment in Telecommunication sector

3. Employment in Educational sector

4. Employment in the service sector

5. Employment in Utilities

6. Employment in Consultancy sector

7. Employment in Construction sector

8. Employment in petroleum sector

9. Employment in farming and food processing sector.

EVALUATION:

I. What is a career?

II. Explain why it is necessary for someone to choose a career.

III. Mention eight job opportunities for technological engineers in a developing country like Nigeria.

ASSIGNMENT: Read New Basic Technology for Junior Secondary School, Bk 3, By P. O Olawehinmi. Pg 128 – 132 and answer the following questions:

a. State two areas where trees are found.

b. List five uses of wood at home.

c. Mention four stages a log of wood must pass through before it becomes workable and useful.

WEEK 2

LESSON 2

TOPIC : PRODUCTION OF MATERIALS.

CONTENT:

1. Production of Wood Materials, Timber Growth and Felling.

2.Properties of good timber preservatives.

3. Common timber defects, twist, bowing, cupping, etc

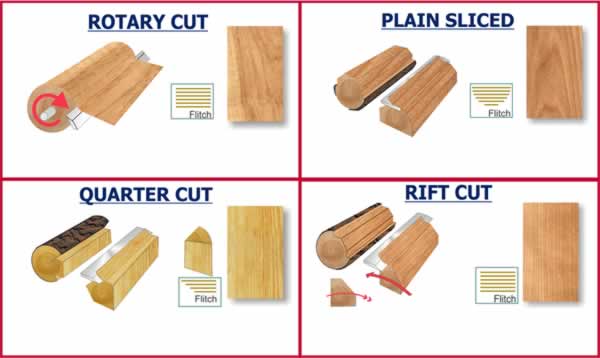

4. Methods of cutting veneers

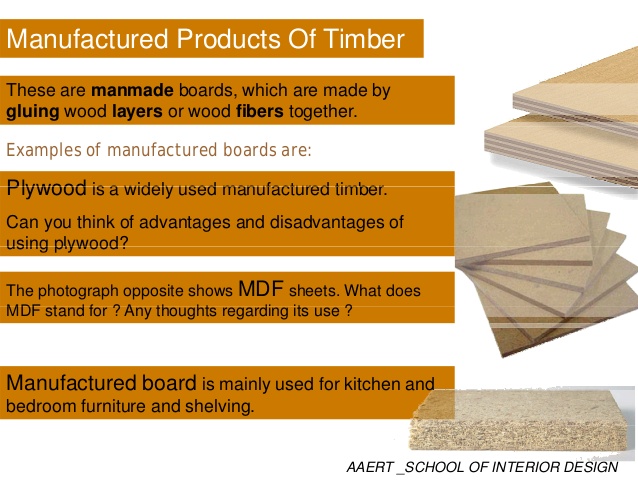

5. Types and manufacture of laminated boards

Production of Wood Materials, Timber Growth and Felling.

Wood is one of the oldest materials in technology. It is composed of cellulose, lignin and other minor materials such as starch, resins, wax and gum. When closely observed, wood is seen to be made up of tiny thread-like units called fibres.

Wood is classified as either hardwood or softwood. The older the tree, the bigger it becomes. When the trees become mature, it is felled by the use of axe or chain saw and sliced into standard market sizes for different purpose in furniture making and construction of buildings.

Hard Wood: These are got from deciduous tree. They have broad leaves and their seeds are enclosed in cases. Some examples include Mahogany, Afara, Opepe, Abura, Omo, Agba, Sapele, Oak, Jarrah and Teak.

Soft Wood : These are got from coniferous trees (i.e. trees that bear naked seeds which are in cones). They have narrow leaves and grow in the temperate regions of the world. Examples include cedar, pine, fir, larch, spruce and European whitewood.

Tree Growth: Trees undergo two types of growth:

1. Primary or vertical growth. This takes place mainly near the tips of the root and shoots of the tree and continues for the most part of the plant’s life.

2. Secondary or horizontal growth. This results in increase in girth and takes place mostly in the cambium.

The stages of processing wood before becoming useful are:

i. Felling

ii. Conversion

iii. Seasoning

iv. Preservation.

TYPES OF TREE:

Deciduous Tree = Hard wood

Coniferous Tree = Soft wood

THE MAIN PARTS OF A TREE.

1) The Roots

2) The Stem / Trunk

3) The branches

4) The bark

5) The Leaves

The felling of trees for timber use is done broadly in two areas in Nigeria.

I. The Free Area

II. The Forest Reserve Area.

1. The Free Area: This is the area outside the forest reserve area and it is owned by individuals. The amount of money paid to the government by the timber contractor for permission to cut down any tree in the Free Area for commercial purposes is called Tariff.

2. The Forest Reserve Area: This is the government owned area. The forest reserved area is guarded by the forest guards. Hence, it is difficult for anybody to cut down any tree in the forest reserve area without the permission from the government. The amount of money paid for the timber to be cut down in the forest reserve area depends on the volume of the trees to be cut down. Hence, this is termed O.T.V i.e Out Turn Volume.

The portable powered saw used in cutting down trees is called Chain saw.

METHODS OF TRANSPORTING LOGS.

Logs are transported from the forest to sawmill, where they are sawn into the required lengths and sizes of planks. Methods of transporting logs are:

I. By Road Transport

II. By Train

III. By Waterways.

CONVERSION OF WOOD.

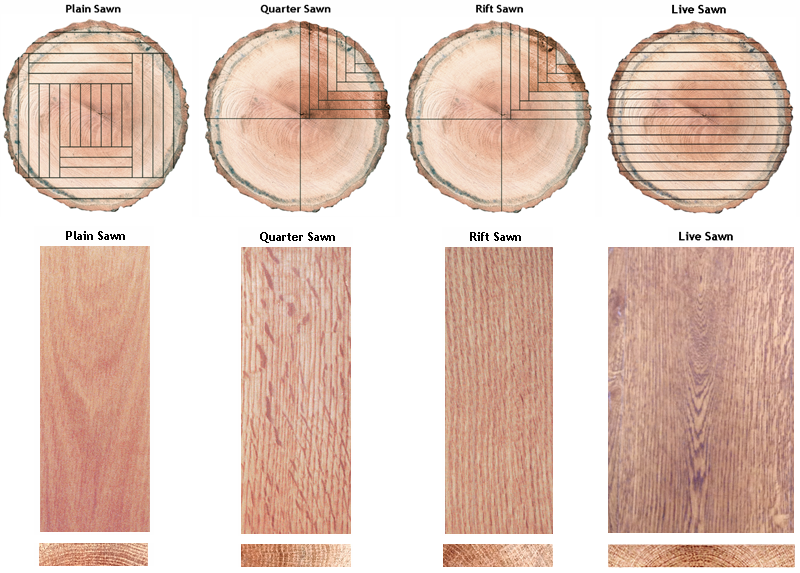

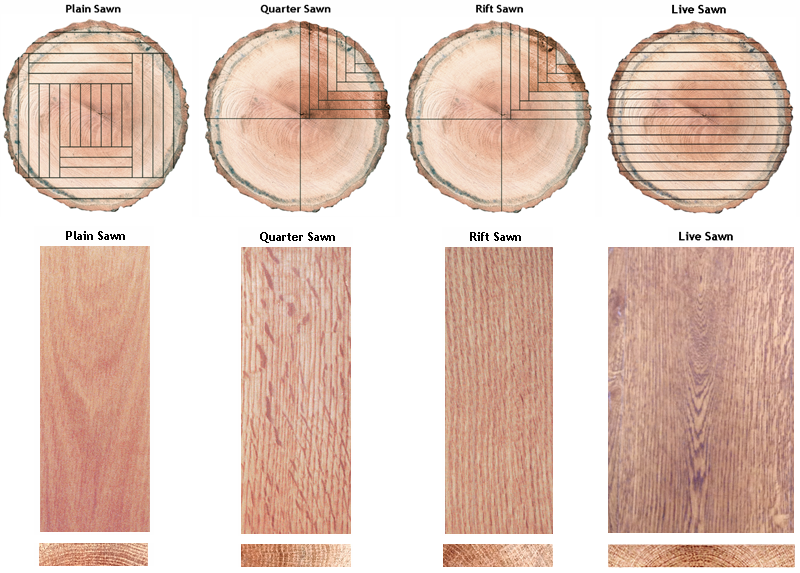

The conversion of wood is the process of sawing logs of timber with wood working machines (Sawing machine) in the Sawmills into planks of required size or marketable size or commercial sizes. The popular methods of conversion of logs of timber into planks are:

I. The plain (through and through) method

II. The quarter sawn method

III. The tangential sawn method

1. Plain Sawn Method: The plain sawn method is also known as through and through method. In plain sawn method, planks are sawn parallel to the axis of the tree trunk. This method of sawing planks is used for producing planks which are needed for doors, windows and roofs of houses. The planks are cut parallel to the axis of the wood.

2. Quarter Sawn Method: This method is simply the sawing of timber plank after plank. The Quarter sawn method is the method of conversion of timber along the rays of the wood. In quarter sawn method, planks are cut at right angles to the growth rings. This method of sawing planks is used for producing planks which are cut with the growth rings running through the thickness of the planks.

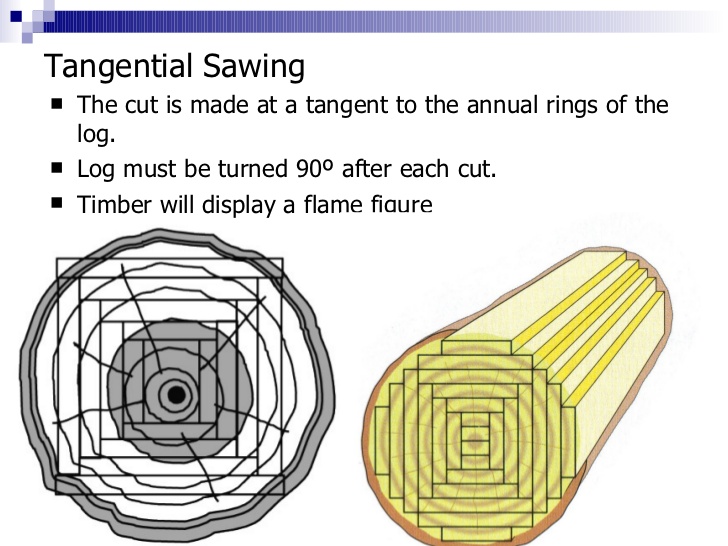

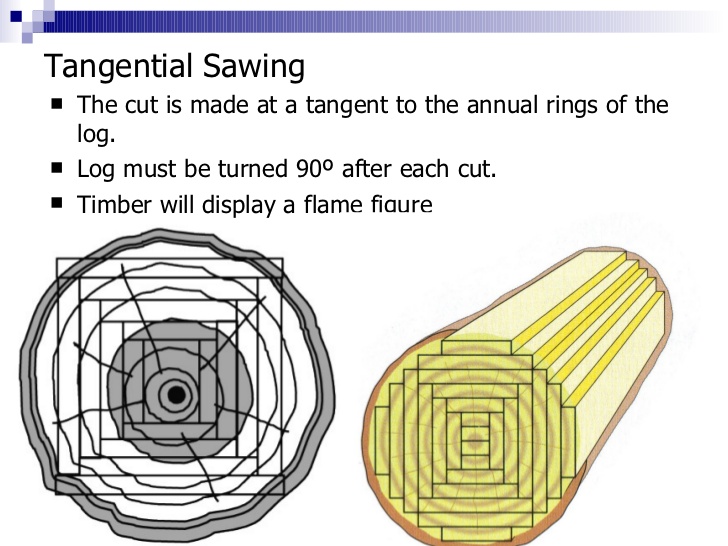

3. Tangential Sawn Method: Tangential sawn method of sawing planks in which the planks are cut so that their wide edges are tangential to the growth rings.

Some of the machines used for conversion of trees are:

a) The circular saw

b) The horizontal log band saw

c) The vertical log band saw

d) The frame saw.

SEASONING OF WOOD.

Wood contains a great deal of water. The water content must be reduced by a process known as seasoning before the wood can become useful. Seasoning of wood is the process of drying or reducing the excess water in the wood. The excess water is called moisture content.

Methods of seasoning wood:

There are two methods of seasoning wood.

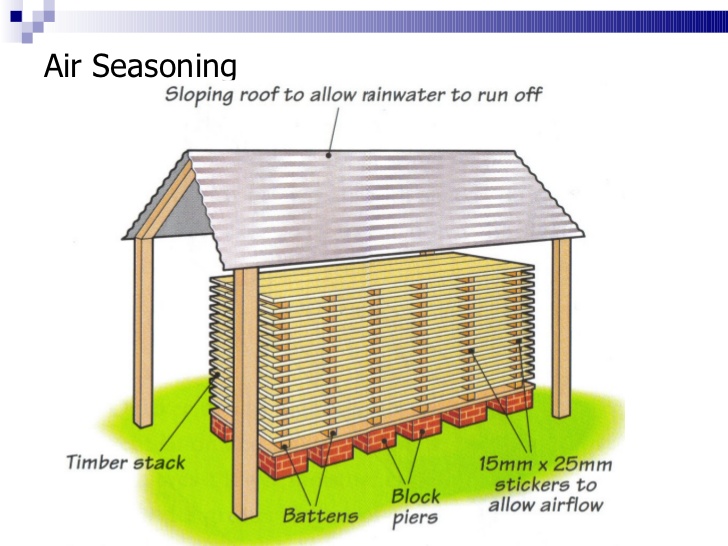

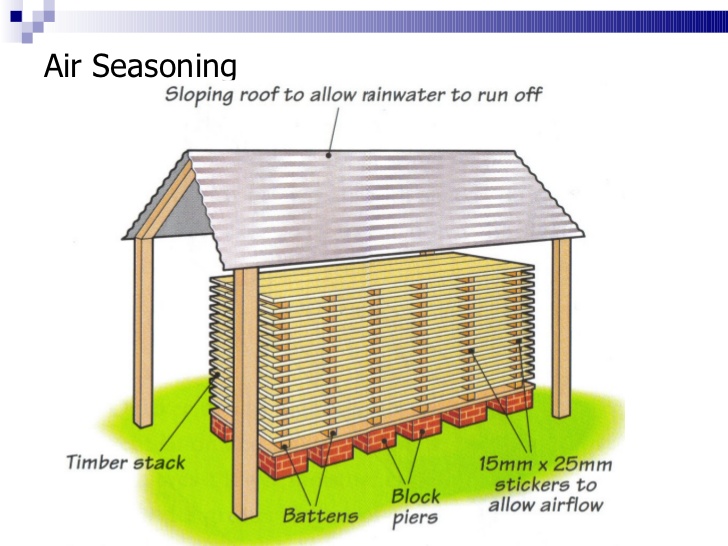

1. The Air seasoning( Natural Seasoning)

2. The Kiln Seasoning ( Artificial Seasoning)

1. The Air Seasoning: This is also called Natural seasoning. This method of seasoning wood involves stacking the wood in the open shed for a long period of time and allows it to dry naturally. The stacked planks (wood) are arranged on top of one another with pieces of small wood called stackers in between them in order to allow the free circulation of air.

Advantages:

It is relatively cheap.

It requires little attention

Disadvantages:

The rate of drying is slow, so it takes a very long time to be seasoned.

There is no control over the drying process.

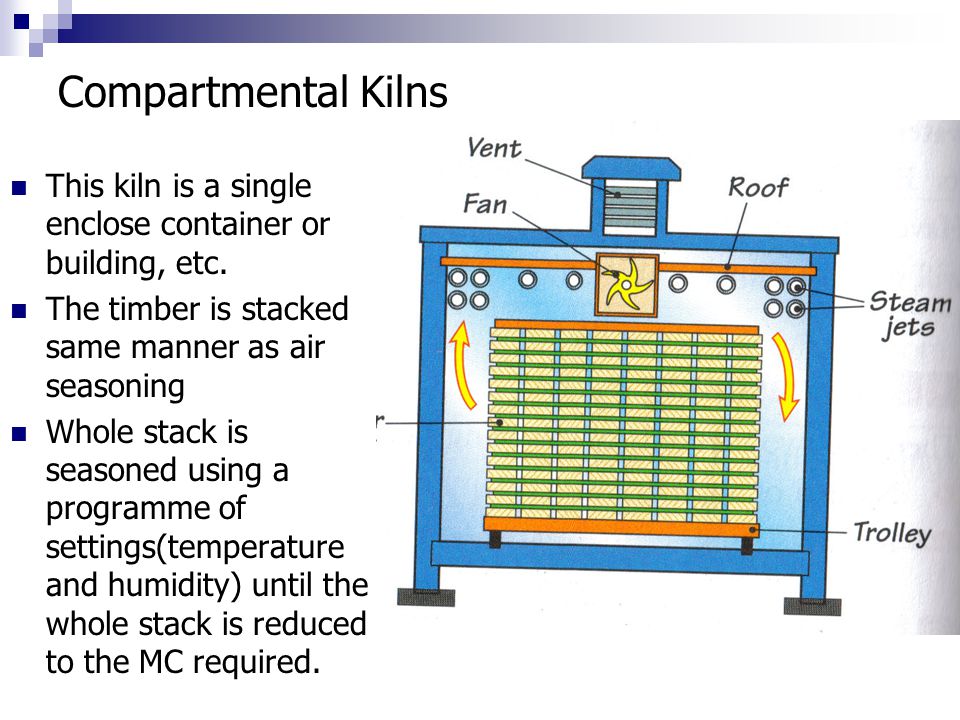

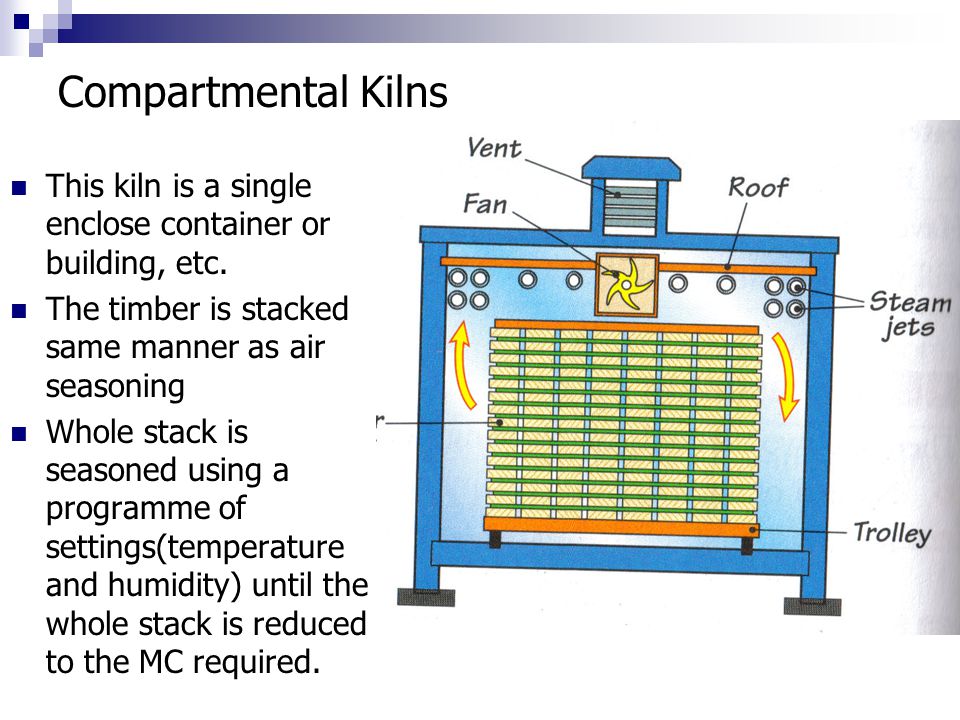

2. The Kiln Seasoning: This method of seasoning wood, involves stacking the timber in a specially heated chamber. The planks are stacked in the same way as in the air seasoning, but the planks are placed in a specially heated chamber called kiln. In this process, the rate of drying planks is faster than air seasoning method.

REASONS FOR SEASONING WOOD

1. It makes the wood become lighter in weight.

2. It makes the wood become more stable.

3. It makes the wood to take paints, polishes and preservatives easily.

4. It makes the wood to be durable i.e. last longer

5. It reduces the attack of fungi and insects on wood.

6. It reduces the moisture content of the wood.

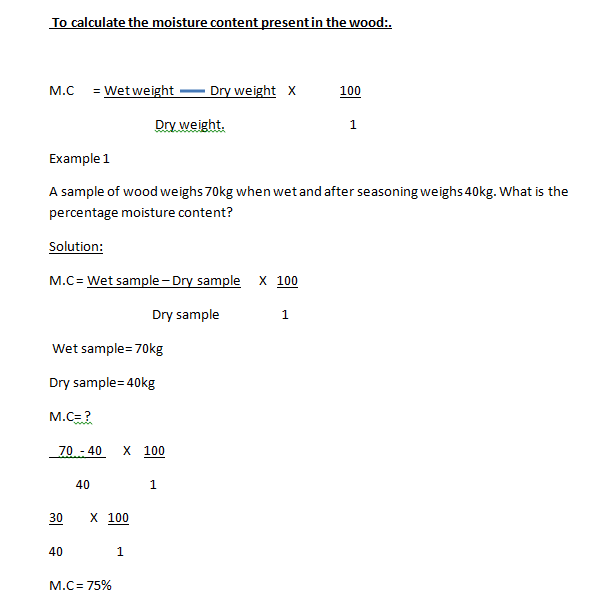

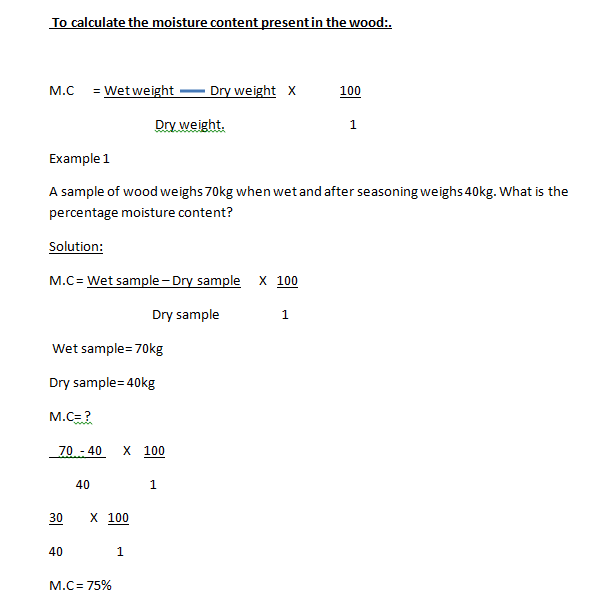

To calculate the moisture content present in the wood:.

Class work.

1. The weight of sample of wood before drying was found to be 120kg. The percentage moisture content was found to be 50%, what is the weight of the sample of the wood after drying?

Answer= 80kg.

2. The weight of a sample of wood after drying was found to be 60kg. The percentage moisture content was 40%, what is the weight of the wood before drying?

Answer= 84kg.

LESSON 3

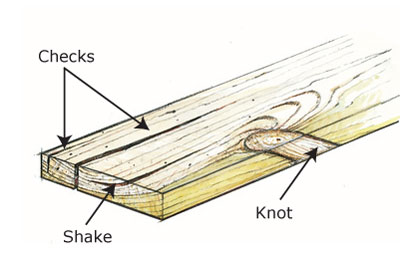

Common Timber Defects

Defects in timber

A defect in timber is any feature in timber that reduces the quality and the market value of the timber.

Types of defects in timber.

Defects in timber can be grouped into two types:

I. The Natural defects

II. The Artificial defects.

THE NATURAL DEFECTS:

The Natural defects in timber are those defects that are caused by natural occurrences such as thunder, rain, growth circumstances etc. Examples of natural defects are:

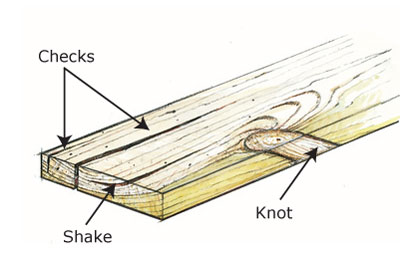

Shakes : These are disruptions in the wood fibre which show up as splits and separation of parts of the stem of a tree.

Examples:

Heart shakes: This is visible on the cross-section of the centre of the log, extending along the rays

Star Shakes: This is similar to the heart shake, but with more spilts like star.

Cup Shakes: These are visible cracks which go round the growth ring of the wood.

Ring Shakes: These are circular cracks on the timber.

Knot: knots are caused by branches.

https://www.slideshare.net/RajatYadav18 ... nd-defects

THE ARTIFICIAL DEFECTS:

The artificial defects are those defects that are caused by human beings through careless handling of the wood while processing.

Examples :

Cup: This is the concave curvature across the face of the timber.

Bow: This is either concave or convex curvature along the length of the plank.

Check: This is the separation of the wood along the grains of the wood.

Twist: This is the spiral form of distortion along the length of the plank.

Insect Attack: This is the visible minute holes seen on the surface of the wood. The insects always attack sap wood.

Warps: The warp in timber is called twists. They are caused by improper seasoning procedures of wood fibers.

https://www.slideshare.net/MrWoodwork/13-diseases

Wood preservation.

This is the process of prolonging the life span of wood by the application of wood preservatives.

Wood preservatives are applied to the planks to prevent insect and fungal attack.

Wood Preservatives: These are the chemicals used to poison the destructive agents in the wood. E.g. fungi, insects, and termites. Some of the chemicals used as the wood preservatives are solignum, creosote, phenols, paints etc.

Types of wood preservatives: There are three major types of wood preservatives depending on the method of mixing.

1. Water soluble preservatives: These are the chemicals that can be mixed thoroughly with water only.

2. Oils soluble preservatives: These are the chemicals that can be mixed thoroughly with oils only.

3. Solvent soluble preservatives: These are the chemicals that can be mixed thoroughly with evaporating liquids only.

Methods of Applying the Preservatives:

The methods of applying good preservatives to dry wood are:

i. Brushing Method: This is the process of using brush to apply preservatives to the wood.

ii. Spraying Method: This is the process of using spraying gun to apply preservatives to the wood.

iii. Cold Immersion Method: This is the method of immersing (dipping) planks in an unheated solution of preservatives for one or two days.

iv. Open Tank Method (Hot and Cold Method): This is the process in which the plank is immersed in a tank containing hot liquid preservatives. This process is normally used for Treating poles and fence posts.

v. Pressure Treatment Method: This is process in which planks are placed inside an enclosed metal cylinder. In the process, the preservatives are being forced into the plank under high pressure. This enables the wood to be preserved either by pumping the solution into the entire cell cavity or by merely coating the cell wall with the preservatives and finally draining the cell cavity, leaving the cell saturated with preservatives, when the process is completed.

Properties of Good preservatives:

The following are the properties of good preservatives:

I. It must be poisonous to the destructive agents.

II. It must be safe to handle

III. It must be permanent to the wood on application

IV. It must be easy to apply on the wood

V. It must be chemically stable for a long time on application to the wood.

LESSON 4

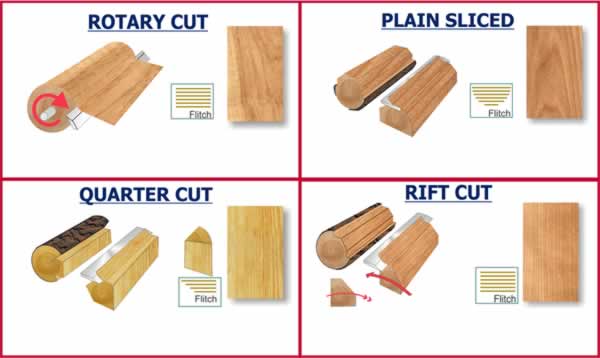

Veneer

Veneers : A veneer is a thin layer of sliced sheet obtained from wood. The thickness of the veneers ranges from 0.5mm – 3.0mm

Method of making veneers

1. Rotary method

2. Slicing method

3. Eccentric method

1. Rotary Method. The rotary method requires the wood to be steamed in other to loosen the fiber and make it easy to peel with knives attached to the lathe machine. With the lathe machine, large sheets of veneers can be produced and cut to marked sizes for commercial purposes.

2. Slicing Method. The timber is safely attached to the slicing machine. The knife or the cutting blade on the machine will be set on the wood depending on the thickness of the veneer required. The thickness is set after every stroke. On switching on the machine, it slices the sheet of wood to the required thickness depending on the purpose of the veneer.

3. Eccentric Peeling. In eccentric peeling method the log of wood is first cut into four parts each of which is called quarter log. Each log is placed on the lathe machine with the sapwood at the centre. The peeling of the veneer commences from the heartwood to the sapwood.

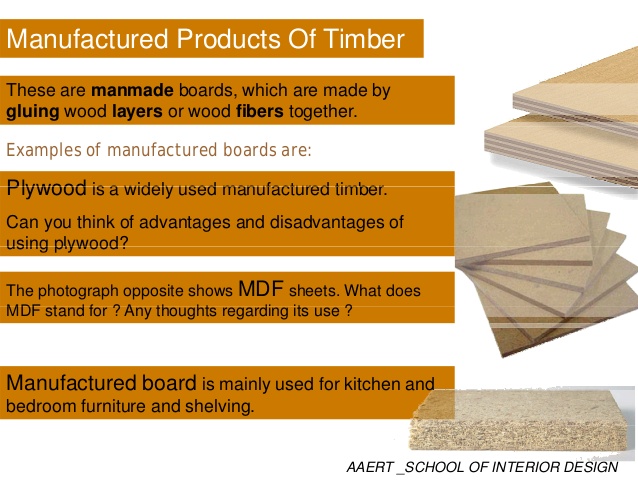

Types and Manufacture of Laminated Boards.

Laminated boards are man-made boards manufactured by man from veneers, wood waste, synthetic and impregnated paper bonds. Types and methods of manufacture of laminated boards are as follows;

1. Examples of Man-made boards.

I. Plywood

II. Particle board

III. Laminated board

IV. Chip board

V. Composite board

VI. Pattern board

VII. Block boards

1. Ply wood

Plywood is produced by bonding three or more veneers together with strong glue. The grain of each sheet of veneer is laid at right angle to each other. After successfully bonding the sheets of veneers together, they are cut in different sizes for commercial purposes such as 2440mm X 1220mm with thickness, ranging from 1 to 25mm.

2. Chipboards. Chipboards are produced with wood chips. The chips which are wastes from wood are mixed with glue. After mixing thoroughly with glue they are pressed together and heated to form boards. The boards can be veneered to form smooth surfaces. Chipboards can be used in the construction of kitchen cabinets.

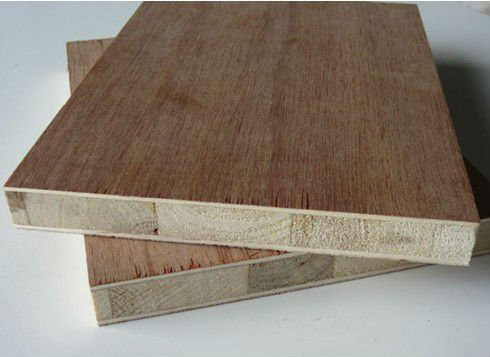

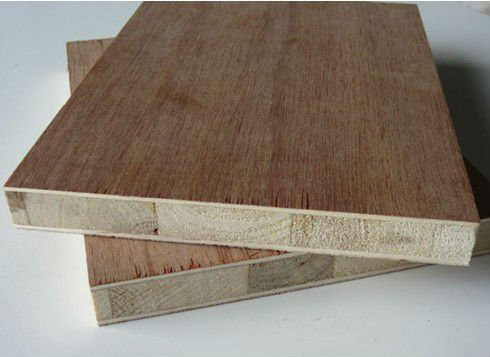

3. Blockboards. Blockboards are made of strips of wood placed side by side and covered with veneers. It is similar to plywood. But it is thicker, stronger and cannot be bent easily. They can be used in the construction of different types of cabinets including tables, cupboards and room dividers.

4. Hardboards :They are manufactured from waste wood mixed and mashed with hardeners and bonding materials like glue. After mixing with glue or any other bonding material they are pressed with great pressure and high temperature. Hardboards can be faced with veneer, enamel and plastics.

5. Laminated Plastics: They are manufactured from synthetic resin and impregnated paper. The materials are bonded together with great pressure and heat is applied. Laminated plastics do not allow the passage of water through them. They are strong and durable.

ADVANTAGES OF MANUFACTURED BOARDS.

Manufactured boards have the following advantages over solid wood.

i. They are available in flat large sheets.

ii. They can be cut easily and worked on.

iii. They can be easily nailed without splitting.

iv. They can be bent to form curves.

v. They do not check or warp like solid wood.

EVALUATION:

1) What is conversion of timber?

2) Mention three methods of conversion of timber.

3) Define seasoning.

4) Give three advantages of seasoning.

5) Mention five defects in timber.

6) List five properties of good wood preservatives.

ASSIGNMENT:

1. Draw a growing tree and label its parts.

2. State the function of each part labeled in (1) above.

3. Give three advantages of manufactured boards over solid wood.

4. Read your textbook ‘ Basic Technology for Junior Secondary School’, By P.O Olawehinmi. Pgs 134-136 Study the topic ‘Production of Metallic Materials’ against the next lesson.

TOPIC : PRODUCTION OF MATERIALS.

CONTENT:

1. Production of Wood Materials, Timber Growth and Felling.

2.Properties of good timber preservatives.

3. Common timber defects, twist, bowing, cupping, etc

4. Methods of cutting veneers

5. Types and manufacture of laminated boards

Production of Wood Materials, Timber Growth and Felling.

Wood is one of the oldest materials in technology. It is composed of cellulose, lignin and other minor materials such as starch, resins, wax and gum. When closely observed, wood is seen to be made up of tiny thread-like units called fibres.

Wood is classified as either hardwood or softwood. The older the tree, the bigger it becomes. When the trees become mature, it is felled by the use of axe or chain saw and sliced into standard market sizes for different purpose in furniture making and construction of buildings.

Hard Wood: These are got from deciduous tree. They have broad leaves and their seeds are enclosed in cases. Some examples include Mahogany, Afara, Opepe, Abura, Omo, Agba, Sapele, Oak, Jarrah and Teak.

Soft Wood : These are got from coniferous trees (i.e. trees that bear naked seeds which are in cones). They have narrow leaves and grow in the temperate regions of the world. Examples include cedar, pine, fir, larch, spruce and European whitewood.

Tree Growth: Trees undergo two types of growth:

1. Primary or vertical growth. This takes place mainly near the tips of the root and shoots of the tree and continues for the most part of the plant’s life.

2. Secondary or horizontal growth. This results in increase in girth and takes place mostly in the cambium.

The stages of processing wood before becoming useful are:

i. Felling

ii. Conversion

iii. Seasoning

iv. Preservation.

TYPES OF TREE:

Deciduous Tree = Hard wood

Coniferous Tree = Soft wood

THE MAIN PARTS OF A TREE.

1) The Roots

2) The Stem / Trunk

3) The branches

4) The bark

5) The Leaves

The felling of trees for timber use is done broadly in two areas in Nigeria.

I. The Free Area

II. The Forest Reserve Area.

1. The Free Area: This is the area outside the forest reserve area and it is owned by individuals. The amount of money paid to the government by the timber contractor for permission to cut down any tree in the Free Area for commercial purposes is called Tariff.

2. The Forest Reserve Area: This is the government owned area. The forest reserved area is guarded by the forest guards. Hence, it is difficult for anybody to cut down any tree in the forest reserve area without the permission from the government. The amount of money paid for the timber to be cut down in the forest reserve area depends on the volume of the trees to be cut down. Hence, this is termed O.T.V i.e Out Turn Volume.

The portable powered saw used in cutting down trees is called Chain saw.

METHODS OF TRANSPORTING LOGS.

Logs are transported from the forest to sawmill, where they are sawn into the required lengths and sizes of planks. Methods of transporting logs are:

I. By Road Transport

II. By Train

III. By Waterways.

CONVERSION OF WOOD.

The conversion of wood is the process of sawing logs of timber with wood working machines (Sawing machine) in the Sawmills into planks of required size or marketable size or commercial sizes. The popular methods of conversion of logs of timber into planks are:

I. The plain (through and through) method

II. The quarter sawn method

III. The tangential sawn method

1. Plain Sawn Method: The plain sawn method is also known as through and through method. In plain sawn method, planks are sawn parallel to the axis of the tree trunk. This method of sawing planks is used for producing planks which are needed for doors, windows and roofs of houses. The planks are cut parallel to the axis of the wood.

2. Quarter Sawn Method: This method is simply the sawing of timber plank after plank. The Quarter sawn method is the method of conversion of timber along the rays of the wood. In quarter sawn method, planks are cut at right angles to the growth rings. This method of sawing planks is used for producing planks which are cut with the growth rings running through the thickness of the planks.

3. Tangential Sawn Method: Tangential sawn method of sawing planks in which the planks are cut so that their wide edges are tangential to the growth rings.

Some of the machines used for conversion of trees are:

a) The circular saw

b) The horizontal log band saw

c) The vertical log band saw

d) The frame saw.

SEASONING OF WOOD.

Wood contains a great deal of water. The water content must be reduced by a process known as seasoning before the wood can become useful. Seasoning of wood is the process of drying or reducing the excess water in the wood. The excess water is called moisture content.

Methods of seasoning wood:

There are two methods of seasoning wood.

1. The Air seasoning( Natural Seasoning)

2. The Kiln Seasoning ( Artificial Seasoning)

1. The Air Seasoning: This is also called Natural seasoning. This method of seasoning wood involves stacking the wood in the open shed for a long period of time and allows it to dry naturally. The stacked planks (wood) are arranged on top of one another with pieces of small wood called stackers in between them in order to allow the free circulation of air.

Advantages:

It is relatively cheap.

It requires little attention

Disadvantages:

The rate of drying is slow, so it takes a very long time to be seasoned.

There is no control over the drying process.

2. The Kiln Seasoning: This method of seasoning wood, involves stacking the timber in a specially heated chamber. The planks are stacked in the same way as in the air seasoning, but the planks are placed in a specially heated chamber called kiln. In this process, the rate of drying planks is faster than air seasoning method.

REASONS FOR SEASONING WOOD

1. It makes the wood become lighter in weight.

2. It makes the wood become more stable.

3. It makes the wood to take paints, polishes and preservatives easily.

4. It makes the wood to be durable i.e. last longer

5. It reduces the attack of fungi and insects on wood.

6. It reduces the moisture content of the wood.

To calculate the moisture content present in the wood:.

Class work.

1. The weight of sample of wood before drying was found to be 120kg. The percentage moisture content was found to be 50%, what is the weight of the sample of the wood after drying?

Answer= 80kg.

2. The weight of a sample of wood after drying was found to be 60kg. The percentage moisture content was 40%, what is the weight of the wood before drying?

Answer= 84kg.

LESSON 3

Common Timber Defects

Defects in timber

A defect in timber is any feature in timber that reduces the quality and the market value of the timber.

Types of defects in timber.

Defects in timber can be grouped into two types:

I. The Natural defects

II. The Artificial defects.

THE NATURAL DEFECTS:

The Natural defects in timber are those defects that are caused by natural occurrences such as thunder, rain, growth circumstances etc. Examples of natural defects are:

Shakes : These are disruptions in the wood fibre which show up as splits and separation of parts of the stem of a tree.

Examples:

Heart shakes: This is visible on the cross-section of the centre of the log, extending along the rays

Star Shakes: This is similar to the heart shake, but with more spilts like star.

Cup Shakes: These are visible cracks which go round the growth ring of the wood.

Ring Shakes: These are circular cracks on the timber.

Knot: knots are caused by branches.

https://www.slideshare.net/RajatYadav18 ... nd-defects

THE ARTIFICIAL DEFECTS:

The artificial defects are those defects that are caused by human beings through careless handling of the wood while processing.

Examples :

Cup: This is the concave curvature across the face of the timber.

Bow: This is either concave or convex curvature along the length of the plank.

Check: This is the separation of the wood along the grains of the wood.

Twist: This is the spiral form of distortion along the length of the plank.

Insect Attack: This is the visible minute holes seen on the surface of the wood. The insects always attack sap wood.

Warps: The warp in timber is called twists. They are caused by improper seasoning procedures of wood fibers.

https://www.slideshare.net/MrWoodwork/13-diseases

Wood preservation.

This is the process of prolonging the life span of wood by the application of wood preservatives.

Wood preservatives are applied to the planks to prevent insect and fungal attack.

Wood Preservatives: These are the chemicals used to poison the destructive agents in the wood. E.g. fungi, insects, and termites. Some of the chemicals used as the wood preservatives are solignum, creosote, phenols, paints etc.

Types of wood preservatives: There are three major types of wood preservatives depending on the method of mixing.

1. Water soluble preservatives: These are the chemicals that can be mixed thoroughly with water only.

2. Oils soluble preservatives: These are the chemicals that can be mixed thoroughly with oils only.

3. Solvent soluble preservatives: These are the chemicals that can be mixed thoroughly with evaporating liquids only.

Methods of Applying the Preservatives:

The methods of applying good preservatives to dry wood are:

i. Brushing Method: This is the process of using brush to apply preservatives to the wood.

ii. Spraying Method: This is the process of using spraying gun to apply preservatives to the wood.

iii. Cold Immersion Method: This is the method of immersing (dipping) planks in an unheated solution of preservatives for one or two days.

iv. Open Tank Method (Hot and Cold Method): This is the process in which the plank is immersed in a tank containing hot liquid preservatives. This process is normally used for Treating poles and fence posts.

v. Pressure Treatment Method: This is process in which planks are placed inside an enclosed metal cylinder. In the process, the preservatives are being forced into the plank under high pressure. This enables the wood to be preserved either by pumping the solution into the entire cell cavity or by merely coating the cell wall with the preservatives and finally draining the cell cavity, leaving the cell saturated with preservatives, when the process is completed.

Properties of Good preservatives:

The following are the properties of good preservatives:

I. It must be poisonous to the destructive agents.

II. It must be safe to handle

III. It must be permanent to the wood on application

IV. It must be easy to apply on the wood

V. It must be chemically stable for a long time on application to the wood.

LESSON 4

Veneer

Veneers : A veneer is a thin layer of sliced sheet obtained from wood. The thickness of the veneers ranges from 0.5mm – 3.0mm

Method of making veneers

1. Rotary method

2. Slicing method

3. Eccentric method

1. Rotary Method. The rotary method requires the wood to be steamed in other to loosen the fiber and make it easy to peel with knives attached to the lathe machine. With the lathe machine, large sheets of veneers can be produced and cut to marked sizes for commercial purposes.

2. Slicing Method. The timber is safely attached to the slicing machine. The knife or the cutting blade on the machine will be set on the wood depending on the thickness of the veneer required. The thickness is set after every stroke. On switching on the machine, it slices the sheet of wood to the required thickness depending on the purpose of the veneer.

3. Eccentric Peeling. In eccentric peeling method the log of wood is first cut into four parts each of which is called quarter log. Each log is placed on the lathe machine with the sapwood at the centre. The peeling of the veneer commences from the heartwood to the sapwood.

Types and Manufacture of Laminated Boards.

Laminated boards are man-made boards manufactured by man from veneers, wood waste, synthetic and impregnated paper bonds. Types and methods of manufacture of laminated boards are as follows;

1. Examples of Man-made boards.

I. Plywood

II. Particle board

III. Laminated board

IV. Chip board

V. Composite board

VI. Pattern board

VII. Block boards

1. Ply wood

Plywood is produced by bonding three or more veneers together with strong glue. The grain of each sheet of veneer is laid at right angle to each other. After successfully bonding the sheets of veneers together, they are cut in different sizes for commercial purposes such as 2440mm X 1220mm with thickness, ranging from 1 to 25mm.

2. Chipboards. Chipboards are produced with wood chips. The chips which are wastes from wood are mixed with glue. After mixing thoroughly with glue they are pressed together and heated to form boards. The boards can be veneered to form smooth surfaces. Chipboards can be used in the construction of kitchen cabinets.

3. Blockboards. Blockboards are made of strips of wood placed side by side and covered with veneers. It is similar to plywood. But it is thicker, stronger and cannot be bent easily. They can be used in the construction of different types of cabinets including tables, cupboards and room dividers.

4. Hardboards :They are manufactured from waste wood mixed and mashed with hardeners and bonding materials like glue. After mixing with glue or any other bonding material they are pressed with great pressure and high temperature. Hardboards can be faced with veneer, enamel and plastics.

5. Laminated Plastics: They are manufactured from synthetic resin and impregnated paper. The materials are bonded together with great pressure and heat is applied. Laminated plastics do not allow the passage of water through them. They are strong and durable.

ADVANTAGES OF MANUFACTURED BOARDS.

Manufactured boards have the following advantages over solid wood.

i. They are available in flat large sheets.

ii. They can be cut easily and worked on.

iii. They can be easily nailed without splitting.

iv. They can be bent to form curves.

v. They do not check or warp like solid wood.

EVALUATION:

1) What is conversion of timber?

2) Mention three methods of conversion of timber.

3) Define seasoning.

4) Give three advantages of seasoning.

5) Mention five defects in timber.

6) List five properties of good wood preservatives.

ASSIGNMENT:

1. Draw a growing tree and label its parts.

2. State the function of each part labeled in (1) above.

3. Give three advantages of manufactured boards over solid wood.

4. Read your textbook ‘ Basic Technology for Junior Secondary School’, By P.O Olawehinmi. Pgs 134-136 Study the topic ‘Production of Metallic Materials’ against the next lesson.

WEEK 3

LESSON 5

TOPIC: PRODUCTION OF METALLIC MATERIALS.

CONTENT :

1. Production of metals: smelting, casting, etc

2. Carbon properties of steels.

3. Metal Alloys

4. Clay, ceramics and glass.

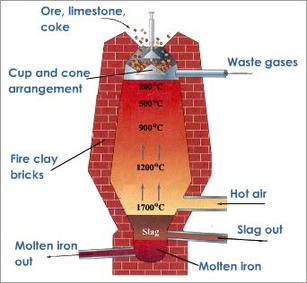

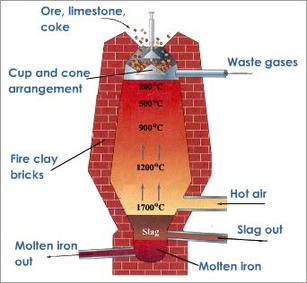

Metallic materials are materials which are referred to as good conductors of heat and electricity. Metals are gotten from Iron ore which is the raw material for metal production. The Iron Ore is dug from the ground along with the impurities (coke, hot air, limestone with Iron Ore).

When the Iron Ore is dug up from the ground, it cannot be used as it contains some impurities, it undergoes certain processes during which these impurities are removed and other substances are added. Since these impurities cannot be removed from iron-ore in its solid state, it is converted into a liquid state by heating. Thus process is known as smelting. The equipment used for this process is called a furnace. After removing these impurities from Iron Ore, the product left is called Pig-Iron.The Pig iron in its ordinary state cannot be used without further processing; this is because pig iron contains saturated iron and carbon. This is weak and can break easily. Hence, it forms the basis of all ferrous metals containing about 45% carbon. In order to render pig iron usable such as cast Iron, steels and wrought Iron, the amount of carbon it contains must be reduced.

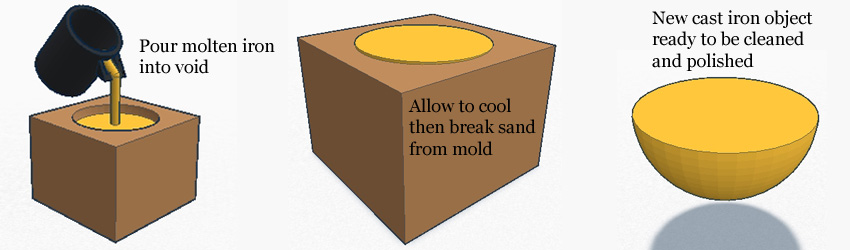

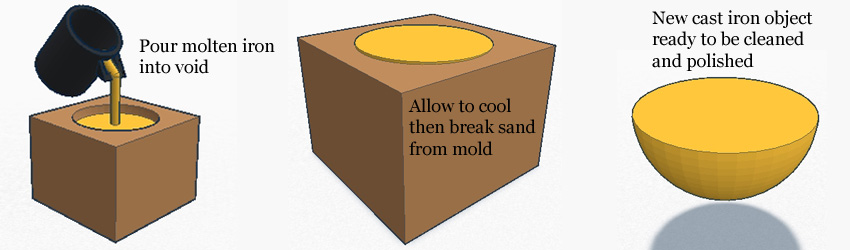

1. Cast Iron: This is obtained when pig Iron is put into a cupola furnace. In this furnace, the carbon content is reduced to about 3.5%. The molten Iron is then poured from the furnace into a container, called mould, so as to solidify it. This process of pouring molten iron into a mould to solidify into a described shape is called casting, hence, the name cast iron.

Examples of cast iron

i. Ductile (chilled) cast iron

ii. Malleable cast iron

iii. Grey cast iron

iv. White cast iron.

2. Steel: This is obtained when the carbon content of pig iron is reduced to 1.5 or less. Steels are named according to the carbon content present in them. These steels are called Plain Carbon Steels because they are made up of carbon and iron.

I. Low carbon steel: (mild steel) this contains about 0.3% or less of carbon.

II. Medium carbon steel: This contain between 0.3%- 0.5% of carbon.

III. High carbon steel: This contains between 0.6%- 1.5% of carbon.

Furnaces used are open hearth and Bessemer converter.

3. Wrought Iron: The wrought iron is obtained by removing the carbon content present in the pig iron. It is soft, easily bent and does not break or rust easily. This is almost pure iron with little slag on it. The wrought iron has no carbon content in them. It is almost rust proof. It is malleable and ductile and can be easily forged into the required shape. Wrought Iron is used in the manufacture of chairs, boilers, plates, gears and so forth.

Casting: This is the process of melting and pouring molten metal into the mould where it cools down to solidify.

Smelting: This is the process of extracting metals from its iron-ore to a liquid state by heating. In this process, all impurities are extracted from the Iron- Ore to form pig-iron.

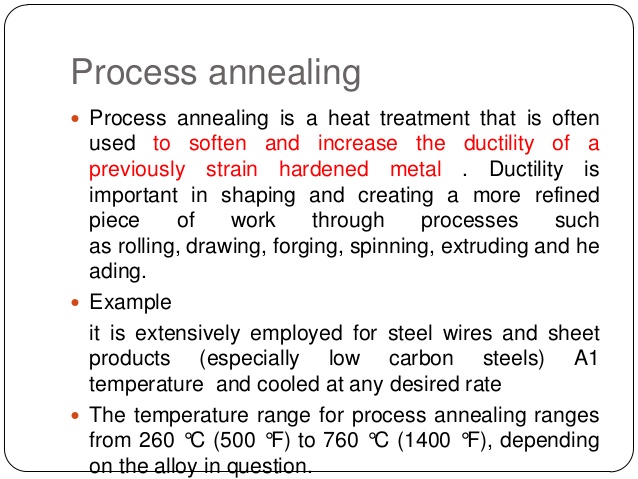

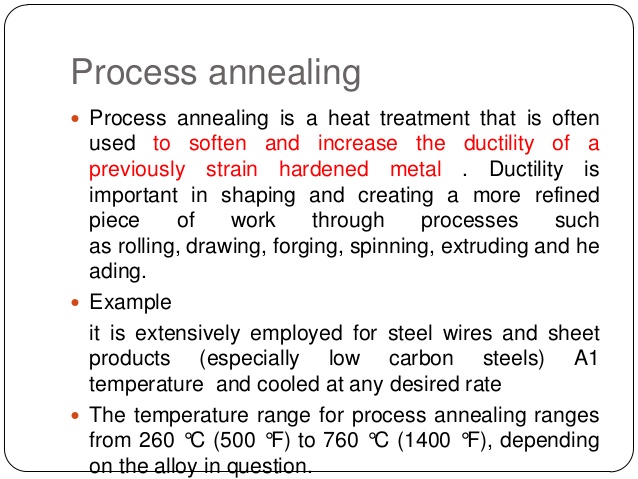

Annealing: This is the process by which metals can be softened.

Alloy steels

All steels are alloys because they contain both iron and carbon. Alloy steel is a combination of plain carbon steel and one or more other elements which are placed in the electric furnace and then heated. This molten mixture is then poured into a mould container and then cooled to solidify. The alloy steels are:

I. High tensile steels: This is also known as Nickel - chrome alloys. These contain iron, carbon, nickel and chromium. They are used for making machine parts which require high tensility and strength.

II. High Speed steels: These contain iron, carbon, tungsten and chromium. Other forms of high speed steels contain cobalt and vanadium. They are used as cutting edges in machines where friction causes excessive heat due to continuous cutting.

III. Stainless steels: These contain Iron, carbon, Nickel or chromium. Nickel and chromium are principally used as coating for the metals so as to make it resistant to corrosion. They are produced in electric furnace.

PROCESSING OF NON-FERROUS METALS:

The non-ferrous metals are the metals which do not have iron content in them, therefore they are not magnetic.

Examples: Copper, Aluminum, Zinc, Gold and Tungsten.

Iron ore is loaded into a furnace and then melted. The desired metal in a molten state is then separated from the mixture. The molten metal is then poured into containers so as to solidify. When this is done on a large scale, a reverberating furnace is used. The furnace is built of clay or other suitable earthen materials and further reinforced with steel on its outer walls.

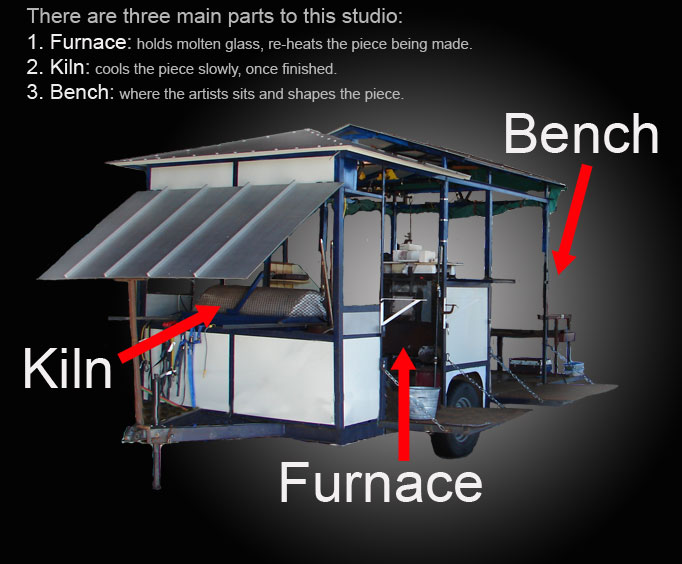

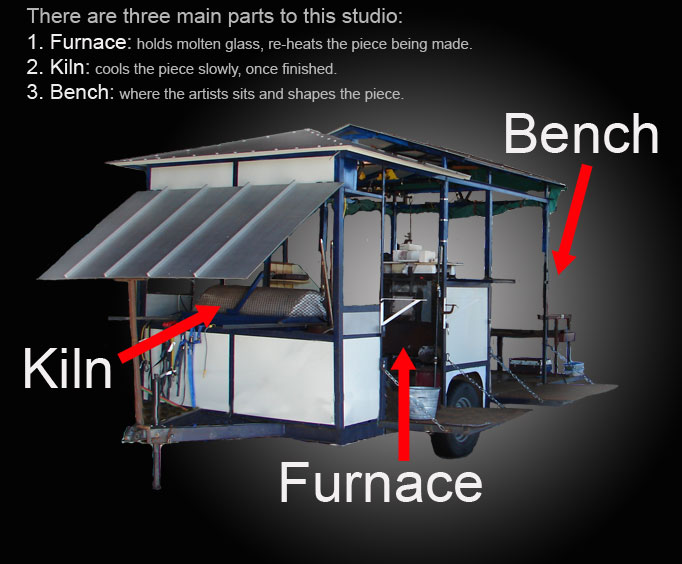

Kiln furnace

A furnace is a solid structure in which a lot of heat energy is generated to produce metal. The different types of furnaces in which different types of metals are produced are:

Blast furnace: This is the structure used for producing pig-iron from Iron Ore.

Bessemer converter: This is the structure used for producing steel from pig iron.

Open hearth furnace: This is the structure used for producing steel from pig-iron.

Electric Arc-furnace: This is the structure used for producing stainless steel.

Cupola furnace: This is the structure used for producing cast iron from pig-iron.

Pudding furnace: This is the structure used for producing wrought-iron.

Reverberating furnace: This is the structure used for producing non-ferrous metals.

LESSON 6

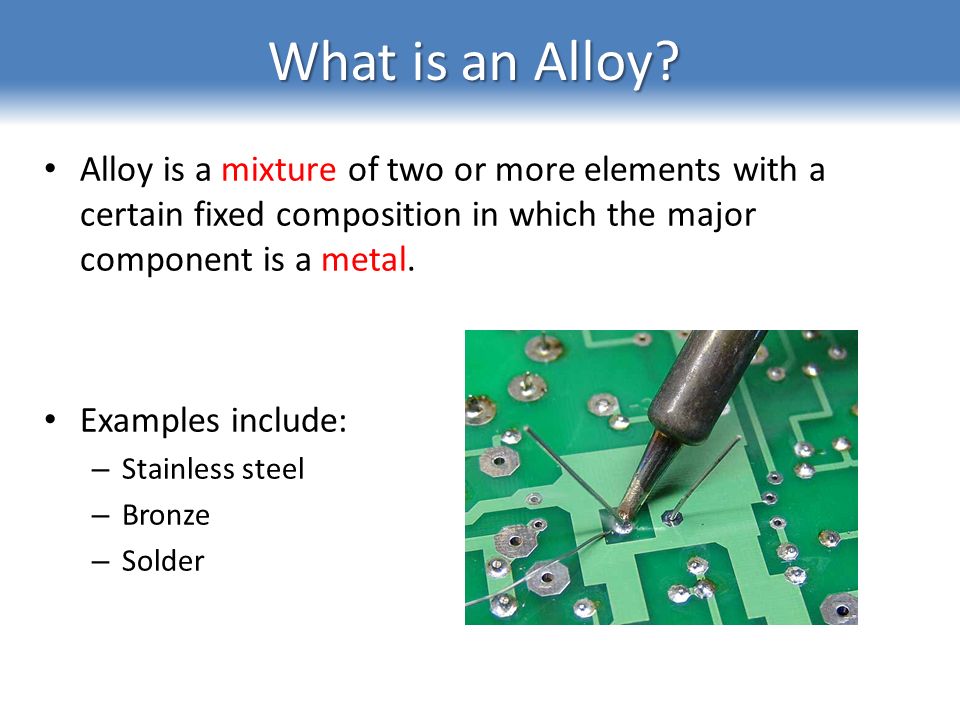

Metal Alloy.

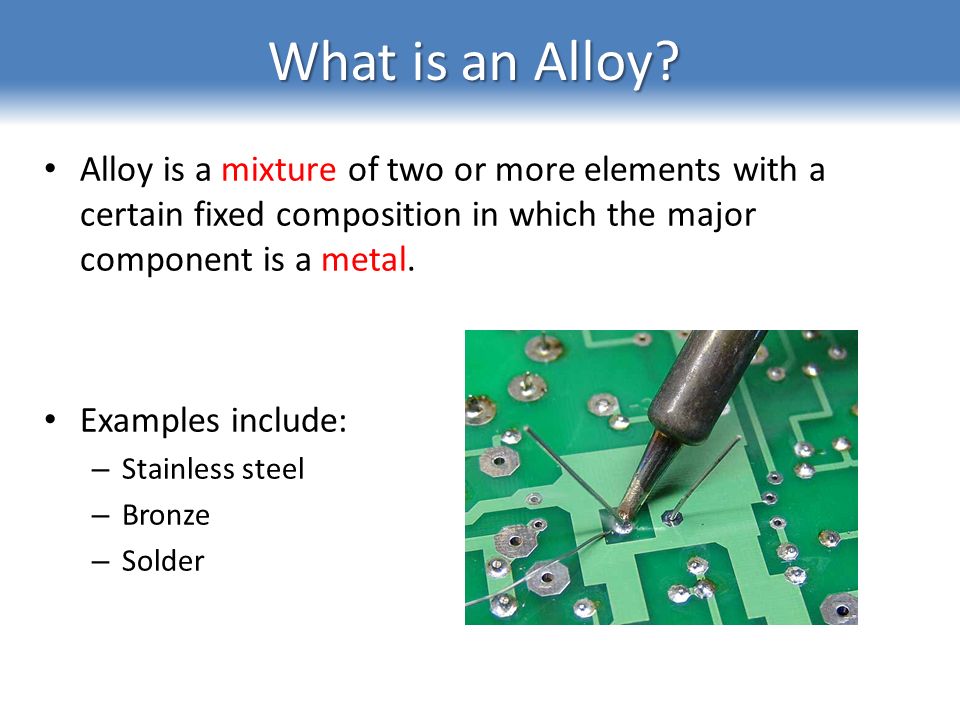

An alloy is a mixture of two or more metals. A non-ferrous alloy is a mixture of two or more non-ferrous metals.

Examples of non-ferrous alloys are Brass, Bronze, Soft Solder, Duralumin, etc.

i. Brass: Brass is a mixture of copper and zinc

Brass= copper + Zinc

ii. Bronze: Bronze is a mixture of copper, Tin and Phosphorus.

Bronze = Copper + Tin + Phosphorus

iii. Soft solder:

Soft solder = Lead + Tin

iv. Duralumin: Duralumin is a mixture of copper, Aluminum and Magnesium

Duralumin = Copper + Aluminum + Magnesium.

Forms of metals.

1) Bars

2) Wires

3) Sheets

4) Rod

5) Pipes

6) Plates

7) Tubes

8) Channels.

9) Square/ Triangular metals, etc

Production of non-metallic materials

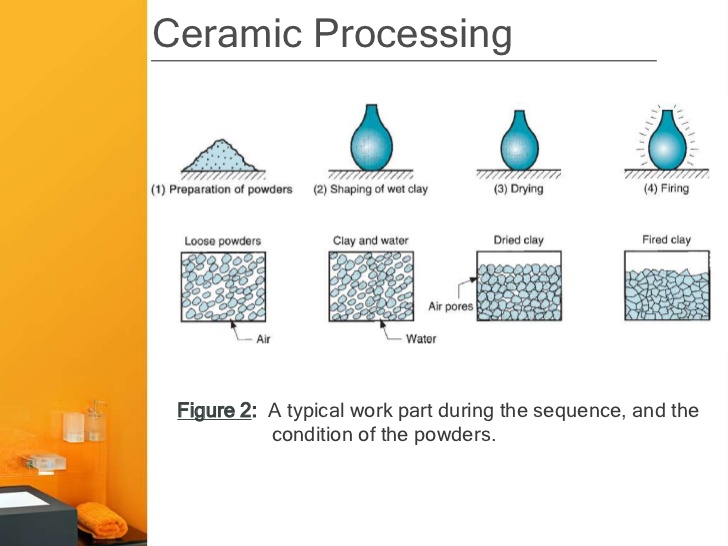

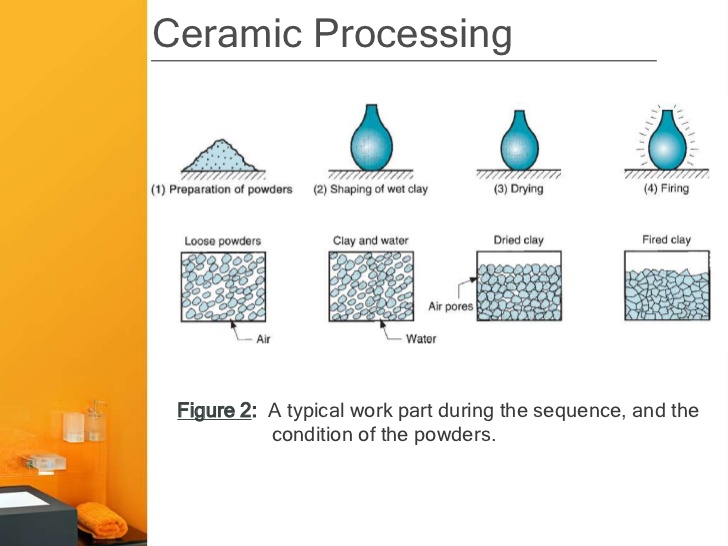

Processing of ceramics:

In the processing of ceramic materials, mud and clay are obtained and cleared of all the impurities. Afterwards, the materials are mixed with water thoroughly pounded until a smooth, even mixture is obtained. The next process is shaping of the mixture into the desired objects. The art of making moist clay materials into various objects is called pottery. There are two methods by which ceramic materials can be processed.

i. The pinch method

ii. The potter’s wheel method.

The Pinch method: This is the traditional method of using fingers to carefully mould and shape objects.

The Potter’s wheel method: This is the method with a rotating disc upon which the clay is mould. There are 4 stages involved in the production of ceramics :

i. Molding

ii. Shaping

iii. Decorating.

iv. Firing.

In pottery the following are involved:

a) Mixing

b) Shaping

c) Drying, and

d) Firing.

Processing of Glass

The mineral glass belongs to the group of ceramics materials; it is made from inorganic resin made from refining petroleum products. Most glasses in use are the inorganic type. Basically, inorganic glass is produced by melting together various proportions of silica, lime-stone, dolomite by firing them in a furnace. The molten substance is allowed to cool slowly through the process called Annealing.

EVALUATION:

I. List 3 examples of ferrous metals.

II. Mention 3 types of cast iron.

III. List 5 furnaces used in metal production.

IV. State any seven forms of metal.

ASSIGNMENT:

Read New Basic Technology for Junior Secondary Schools Bk 3 by P.O Olawehinmi. Pg 137 on Production of Plastics and Rubber.

TOPIC: PRODUCTION OF METALLIC MATERIALS.

CONTENT :

1. Production of metals: smelting, casting, etc

2. Carbon properties of steels.

3. Metal Alloys

4. Clay, ceramics and glass.

Metallic materials are materials which are referred to as good conductors of heat and electricity. Metals are gotten from Iron ore which is the raw material for metal production. The Iron Ore is dug from the ground along with the impurities (coke, hot air, limestone with Iron Ore).

When the Iron Ore is dug up from the ground, it cannot be used as it contains some impurities, it undergoes certain processes during which these impurities are removed and other substances are added. Since these impurities cannot be removed from iron-ore in its solid state, it is converted into a liquid state by heating. Thus process is known as smelting. The equipment used for this process is called a furnace. After removing these impurities from Iron Ore, the product left is called Pig-Iron.The Pig iron in its ordinary state cannot be used without further processing; this is because pig iron contains saturated iron and carbon. This is weak and can break easily. Hence, it forms the basis of all ferrous metals containing about 45% carbon. In order to render pig iron usable such as cast Iron, steels and wrought Iron, the amount of carbon it contains must be reduced.

1. Cast Iron: This is obtained when pig Iron is put into a cupola furnace. In this furnace, the carbon content is reduced to about 3.5%. The molten Iron is then poured from the furnace into a container, called mould, so as to solidify it. This process of pouring molten iron into a mould to solidify into a described shape is called casting, hence, the name cast iron.

Examples of cast iron

i. Ductile (chilled) cast iron

ii. Malleable cast iron

iii. Grey cast iron

iv. White cast iron.

2. Steel: This is obtained when the carbon content of pig iron is reduced to 1.5 or less. Steels are named according to the carbon content present in them. These steels are called Plain Carbon Steels because they are made up of carbon and iron.

I. Low carbon steel: (mild steel) this contains about 0.3% or less of carbon.

II. Medium carbon steel: This contain between 0.3%- 0.5% of carbon.

III. High carbon steel: This contains between 0.6%- 1.5% of carbon.

Furnaces used are open hearth and Bessemer converter.

3. Wrought Iron: The wrought iron is obtained by removing the carbon content present in the pig iron. It is soft, easily bent and does not break or rust easily. This is almost pure iron with little slag on it. The wrought iron has no carbon content in them. It is almost rust proof. It is malleable and ductile and can be easily forged into the required shape. Wrought Iron is used in the manufacture of chairs, boilers, plates, gears and so forth.

Casting: This is the process of melting and pouring molten metal into the mould where it cools down to solidify.

Smelting: This is the process of extracting metals from its iron-ore to a liquid state by heating. In this process, all impurities are extracted from the Iron- Ore to form pig-iron.

Annealing: This is the process by which metals can be softened.

Alloy steels

All steels are alloys because they contain both iron and carbon. Alloy steel is a combination of plain carbon steel and one or more other elements which are placed in the electric furnace and then heated. This molten mixture is then poured into a mould container and then cooled to solidify. The alloy steels are:

I. High tensile steels: This is also known as Nickel - chrome alloys. These contain iron, carbon, nickel and chromium. They are used for making machine parts which require high tensility and strength.

II. High Speed steels: These contain iron, carbon, tungsten and chromium. Other forms of high speed steels contain cobalt and vanadium. They are used as cutting edges in machines where friction causes excessive heat due to continuous cutting.

III. Stainless steels: These contain Iron, carbon, Nickel or chromium. Nickel and chromium are principally used as coating for the metals so as to make it resistant to corrosion. They are produced in electric furnace.

PROCESSING OF NON-FERROUS METALS:

The non-ferrous metals are the metals which do not have iron content in them, therefore they are not magnetic.

Examples: Copper, Aluminum, Zinc, Gold and Tungsten.

Iron ore is loaded into a furnace and then melted. The desired metal in a molten state is then separated from the mixture. The molten metal is then poured into containers so as to solidify. When this is done on a large scale, a reverberating furnace is used. The furnace is built of clay or other suitable earthen materials and further reinforced with steel on its outer walls.

Kiln furnace

A furnace is a solid structure in which a lot of heat energy is generated to produce metal. The different types of furnaces in which different types of metals are produced are:

Blast furnace: This is the structure used for producing pig-iron from Iron Ore.

Bessemer converter: This is the structure used for producing steel from pig iron.

Open hearth furnace: This is the structure used for producing steel from pig-iron.

Electric Arc-furnace: This is the structure used for producing stainless steel.

Cupola furnace: This is the structure used for producing cast iron from pig-iron.

Pudding furnace: This is the structure used for producing wrought-iron.

Reverberating furnace: This is the structure used for producing non-ferrous metals.

LESSON 6

Metal Alloy.

An alloy is a mixture of two or more metals. A non-ferrous alloy is a mixture of two or more non-ferrous metals.

Examples of non-ferrous alloys are Brass, Bronze, Soft Solder, Duralumin, etc.

i. Brass: Brass is a mixture of copper and zinc

Brass= copper + Zinc

ii. Bronze: Bronze is a mixture of copper, Tin and Phosphorus.

Bronze = Copper + Tin + Phosphorus

iii. Soft solder:

Soft solder = Lead + Tin

iv. Duralumin: Duralumin is a mixture of copper, Aluminum and Magnesium

Duralumin = Copper + Aluminum + Magnesium.

Forms of metals.

1) Bars

2) Wires

3) Sheets

4) Rod

5) Pipes

6) Plates

7) Tubes

8) Channels.

9) Square/ Triangular metals, etc

Production of non-metallic materials

Processing of ceramics:

In the processing of ceramic materials, mud and clay are obtained and cleared of all the impurities. Afterwards, the materials are mixed with water thoroughly pounded until a smooth, even mixture is obtained. The next process is shaping of the mixture into the desired objects. The art of making moist clay materials into various objects is called pottery. There are two methods by which ceramic materials can be processed.

i. The pinch method

ii. The potter’s wheel method.

The Pinch method: This is the traditional method of using fingers to carefully mould and shape objects.

The Potter’s wheel method: This is the method with a rotating disc upon which the clay is mould. There are 4 stages involved in the production of ceramics :

i. Molding

ii. Shaping

iii. Decorating.

iv. Firing.

In pottery the following are involved:

a) Mixing

b) Shaping

c) Drying, and

d) Firing.

Processing of Glass

The mineral glass belongs to the group of ceramics materials; it is made from inorganic resin made from refining petroleum products. Most glasses in use are the inorganic type. Basically, inorganic glass is produced by melting together various proportions of silica, lime-stone, dolomite by firing them in a furnace. The molten substance is allowed to cool slowly through the process called Annealing.

EVALUATION:

I. List 3 examples of ferrous metals.

II. Mention 3 types of cast iron.

III. List 5 furnaces used in metal production.

IV. State any seven forms of metal.

ASSIGNMENT:

Read New Basic Technology for Junior Secondary Schools Bk 3 by P.O Olawehinmi. Pg 137 on Production of Plastics and Rubber.

WEEK 4

LESSON 8

TOPIC: PRODUCTION OF MATERIALS (PLASTICS AND RUBBER)

Content:

1.Methods of producing plastics

2. Methods of producing rubber materials; natural and synthetic Rubber

Methods of producing plastics

Plastics

Plastics are commonly used both as household items and in big industries. Ordinarily, it is known as a non-metallic lightweight material which comes in various colors. The manufacture of plastics involves the combination of several different components chiefly obtained from petroleum, cellulose, and coal.

Properties of Plastics

I. Plastics are light weight materials, much lighter than wood, ceramics and metals.

II. They have low resistance to heat. They are easily deformed by heat.

III. They do not rust or corrode.

IV. They are good insulators of heat and electricity and that is why they are used as handles of pots, pressing irons, plugs, etc.

Classification of Plastics.

Plastics are of two types: Thermoplastics and Thermoset.

Thermoplastics. These are plastics which become molten again under heat and can therefore be remolded. Examples include most plastic articles used in the homes such as cups, buckets, jerry cans etc.

Thermoset. They are those plastics which cannot be melted into liquid form by heating. Examples are those used in handles of pressing irons, knives and cooking pots. Thermosets are used where high temperature is anticipated.

Manufacturing and Processing of Plastics.

Plastics are derived from organic materials obtained from petroleum. Its production can simply be broken up into the following stages:

i. Obtaining the basic unit called monomer from petroleum.

ii. Polymerization (i.e. joining a large number of molecules) of the monomer to form resins.

iii. Combining the resin with appropriate materials to produce the required plastics.

iv. Molding and shaping of the plastics into different forms.

Methods of producing plastics.

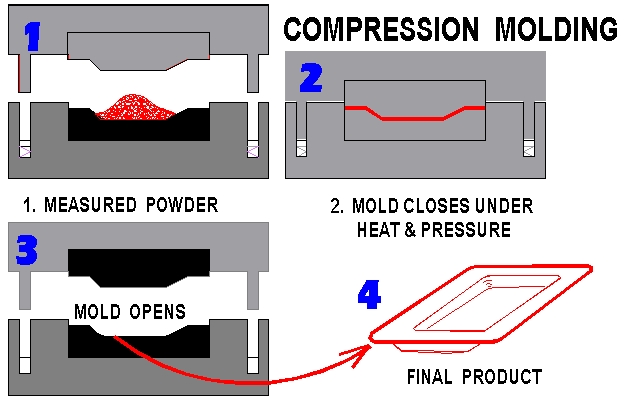

The plastic materials can be molded into any of the required form into any of the required shape when wet through any of the following processes.

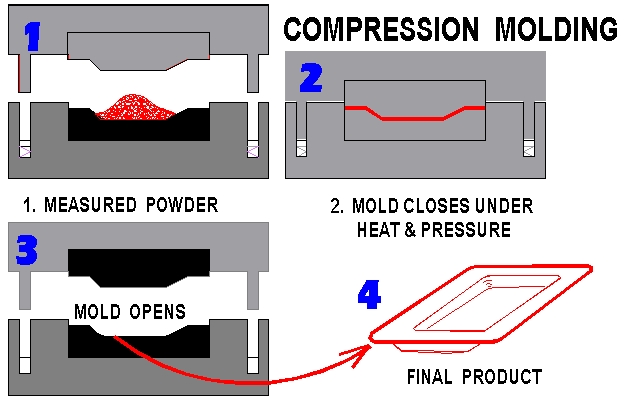

i. The compression molding

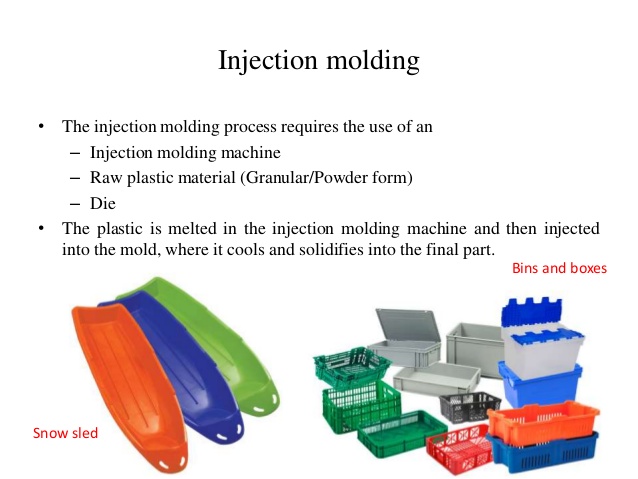

ii. The Injection molding

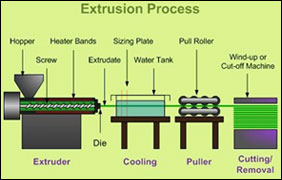

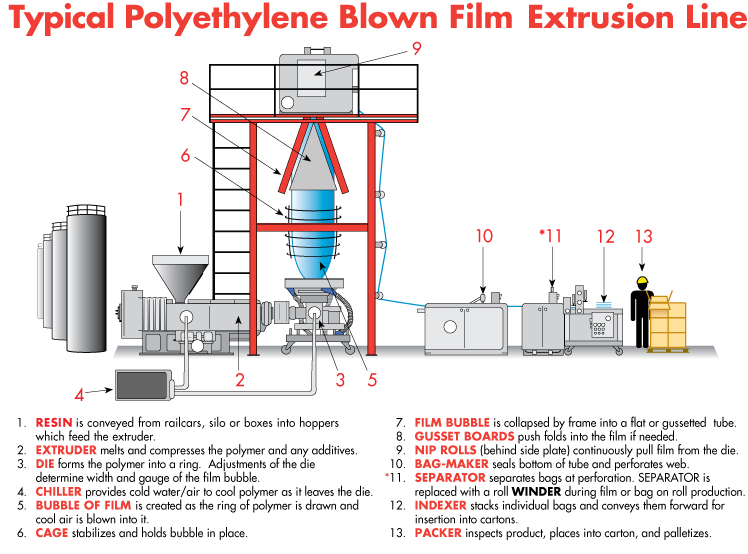

iii. The Extrusion

iv. The Calendaring

v. The Vacuum forming.

The compression molding: This is the method of forming plastic materials in a mould by means of the application of pressure and heat energy. This method is employed in forming thermoset plastics.

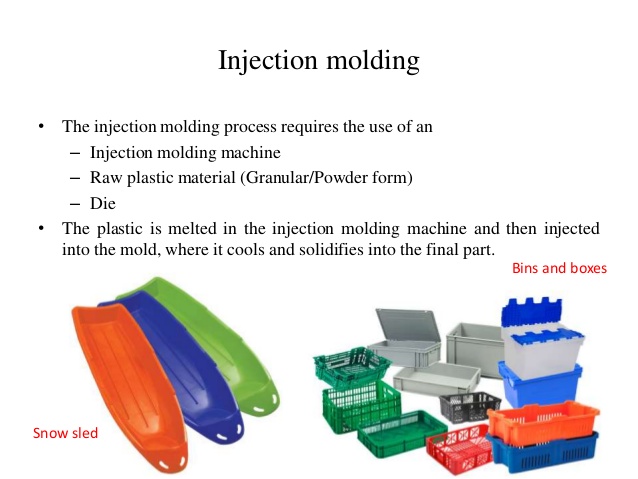

The injection molding: This is a method of forming an object by injecting hot molten metals by means of plungers.

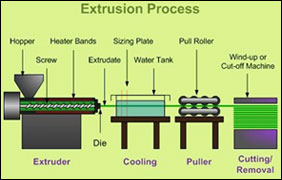

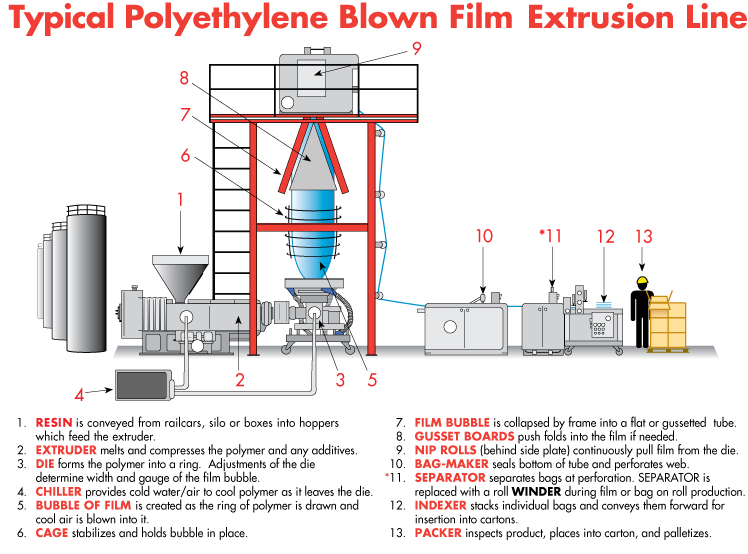

The Extrusion: This is the method of heating a plastic material and forcing it through a mould followed by continuous cooling. It is a method used in the manufacture of thermoplastic pipes.

The Calendaring: This is a method for producing thermoplastic sheets in paste form between heated and cooled rollers.

https://youtu.be/r43qiRRVm8I

The Vacuum forming: This is an enclosed method from which air had been completely removed. It is a method for making plastic cups.

LESSON 9

Methods of Processing rubber.

Rubber: is an elastic organic material. Rubber can easily be stretched, and it can return to its original position when the force is released. There are two types of rubber—natural rubber and synthetic rubber.

Properties of Rubber

I. They are elastic.

II. They are water resistant and will float on water. This is why they are used as floats for swimming.

III. They are good electrical insulators. This is why electric wires are covered with rubber.

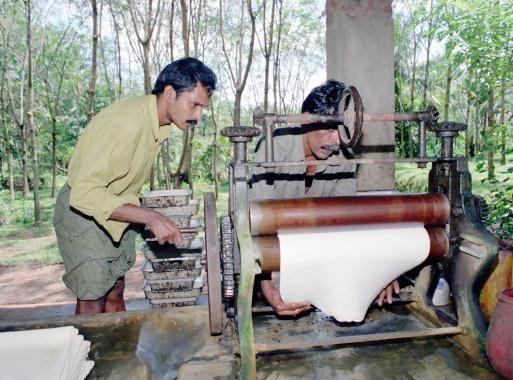

Manufacture and Processing of Rubber.

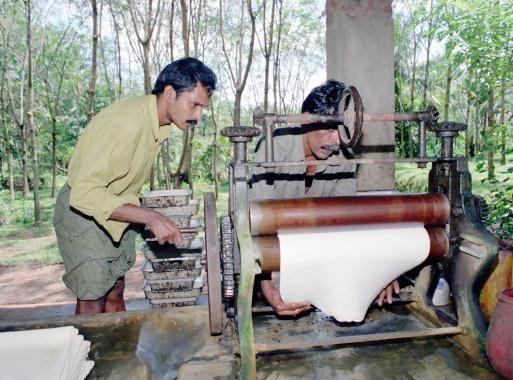

Natural rubber is made from latex ( a milky white liquid) obtained from the rubber tree-‘ Hevea brasiliensis.’ Synthetic rubber on the other hand is obtained from petroleum products. The Natural Latex as found in nature is a white milky sap like fluid. This is used as the raw material for manufacturing natural Rubber. It is extracted from rubber trees.

The synthetic rubber also called neoprene (artificial rubber) is produced by the combination of various chemicals, coal, lime stone, water and sodium chloride by process called polymerization.

Properties of ordinary rubber are not very desirable since they wear out and scratch easily. It needs to be vulcanized to improve its properties. In vulcanization, sulphur is added to the ordinary rubber at high temperatures in the presence of some other compounds. Rubber products are shaped into their form by a number of processes which you will learn about in future.

Carbon black, produced mainly by burning crude oil in special furnaces, is used in tyre compound as reinforcing filler.

Vulcanization of Rubber: The process of improving the quality of rubber by adding sulphur and other chemicals to rubber so as to make the rubber stronger and more elastic.

Uses of Rubber:

• Rubber is a very good shock absorber and is therefore used for making soles of shoes as well as tyres and inner tubes for motor vehicles

• It is also used for making rubber sandals, rainboots, catapults, etc

• For covering electric wires.

The manufacturing of rubber can be processed by any on the following methods:

i. The vacuum forming

ii. The Extrusion

iii. The Calendaring

iv. The compression molding.

EVALUATION:

1) The art of making moist clay materials into various objects is called-----------------

2) The type of rubber produced from petroleum products is known as-----------------

3) The natural rubber is made from a white milky liquid content called-----------------

4) In pottery, clay is mixed with water and pounded to remove---------------------------

Answers: Pottery, Synthetic rubber, Latex, Pebbles.

5) The following are methods of processing plastics EXCEPT

A. Calendaring. B. Extraction C. Injection molding D. Compression molding E. Vacuum Forming.

ASSIGNMENT: Read New Basic Technology for Junior Secondary School, By

P.O Olawehinmi. Pg 139-141. Study the topic ‘Drawing Practice against the next lesson’.

TOPIC: PRODUCTION OF MATERIALS (PLASTICS AND RUBBER)

Content:

1.Methods of producing plastics

2. Methods of producing rubber materials; natural and synthetic Rubber

Methods of producing plastics

Plastics

Plastics are commonly used both as household items and in big industries. Ordinarily, it is known as a non-metallic lightweight material which comes in various colors. The manufacture of plastics involves the combination of several different components chiefly obtained from petroleum, cellulose, and coal.

Properties of Plastics

I. Plastics are light weight materials, much lighter than wood, ceramics and metals.

II. They have low resistance to heat. They are easily deformed by heat.

III. They do not rust or corrode.

IV. They are good insulators of heat and electricity and that is why they are used as handles of pots, pressing irons, plugs, etc.

Classification of Plastics.

Plastics are of two types: Thermoplastics and Thermoset.

Thermoplastics. These are plastics which become molten again under heat and can therefore be remolded. Examples include most plastic articles used in the homes such as cups, buckets, jerry cans etc.

Thermoset. They are those plastics which cannot be melted into liquid form by heating. Examples are those used in handles of pressing irons, knives and cooking pots. Thermosets are used where high temperature is anticipated.

Manufacturing and Processing of Plastics.

Plastics are derived from organic materials obtained from petroleum. Its production can simply be broken up into the following stages:

i. Obtaining the basic unit called monomer from petroleum.

ii. Polymerization (i.e. joining a large number of molecules) of the monomer to form resins.

iii. Combining the resin with appropriate materials to produce the required plastics.

iv. Molding and shaping of the plastics into different forms.

Methods of producing plastics.

The plastic materials can be molded into any of the required form into any of the required shape when wet through any of the following processes.

i. The compression molding

ii. The Injection molding

iii. The Extrusion

iv. The Calendaring

v. The Vacuum forming.

The compression molding: This is the method of forming plastic materials in a mould by means of the application of pressure and heat energy. This method is employed in forming thermoset plastics.

The injection molding: This is a method of forming an object by injecting hot molten metals by means of plungers.

The Extrusion: This is the method of heating a plastic material and forcing it through a mould followed by continuous cooling. It is a method used in the manufacture of thermoplastic pipes.

The Calendaring: This is a method for producing thermoplastic sheets in paste form between heated and cooled rollers.

https://youtu.be/r43qiRRVm8I

The Vacuum forming: This is an enclosed method from which air had been completely removed. It is a method for making plastic cups.

LESSON 9

Methods of Processing rubber.

Rubber: is an elastic organic material. Rubber can easily be stretched, and it can return to its original position when the force is released. There are two types of rubber—natural rubber and synthetic rubber.

Properties of Rubber

I. They are elastic.

II. They are water resistant and will float on water. This is why they are used as floats for swimming.

III. They are good electrical insulators. This is why electric wires are covered with rubber.

Manufacture and Processing of Rubber.

Natural rubber is made from latex ( a milky white liquid) obtained from the rubber tree-‘ Hevea brasiliensis.’ Synthetic rubber on the other hand is obtained from petroleum products. The Natural Latex as found in nature is a white milky sap like fluid. This is used as the raw material for manufacturing natural Rubber. It is extracted from rubber trees.

The synthetic rubber also called neoprene (artificial rubber) is produced by the combination of various chemicals, coal, lime stone, water and sodium chloride by process called polymerization.

Properties of ordinary rubber are not very desirable since they wear out and scratch easily. It needs to be vulcanized to improve its properties. In vulcanization, sulphur is added to the ordinary rubber at high temperatures in the presence of some other compounds. Rubber products are shaped into their form by a number of processes which you will learn about in future.

Carbon black, produced mainly by burning crude oil in special furnaces, is used in tyre compound as reinforcing filler.

Vulcanization of Rubber: The process of improving the quality of rubber by adding sulphur and other chemicals to rubber so as to make the rubber stronger and more elastic.

Uses of Rubber:

• Rubber is a very good shock absorber and is therefore used for making soles of shoes as well as tyres and inner tubes for motor vehicles

• It is also used for making rubber sandals, rainboots, catapults, etc

• For covering electric wires.

The manufacturing of rubber can be processed by any on the following methods:

i. The vacuum forming

ii. The Extrusion

iii. The Calendaring

iv. The compression molding.

EVALUATION:

1) The art of making moist clay materials into various objects is called-----------------

2) The type of rubber produced from petroleum products is known as-----------------

3) The natural rubber is made from a white milky liquid content called-----------------

4) In pottery, clay is mixed with water and pounded to remove---------------------------

Answers: Pottery, Synthetic rubber, Latex, Pebbles.

5) The following are methods of processing plastics EXCEPT

A. Calendaring. B. Extraction C. Injection molding D. Compression molding E. Vacuum Forming.

ASSIGNMENT: Read New Basic Technology for Junior Secondary School, By

P.O Olawehinmi. Pg 139-141. Study the topic ‘Drawing Practice against the next lesson’.

WEEK 5

LESSON 10

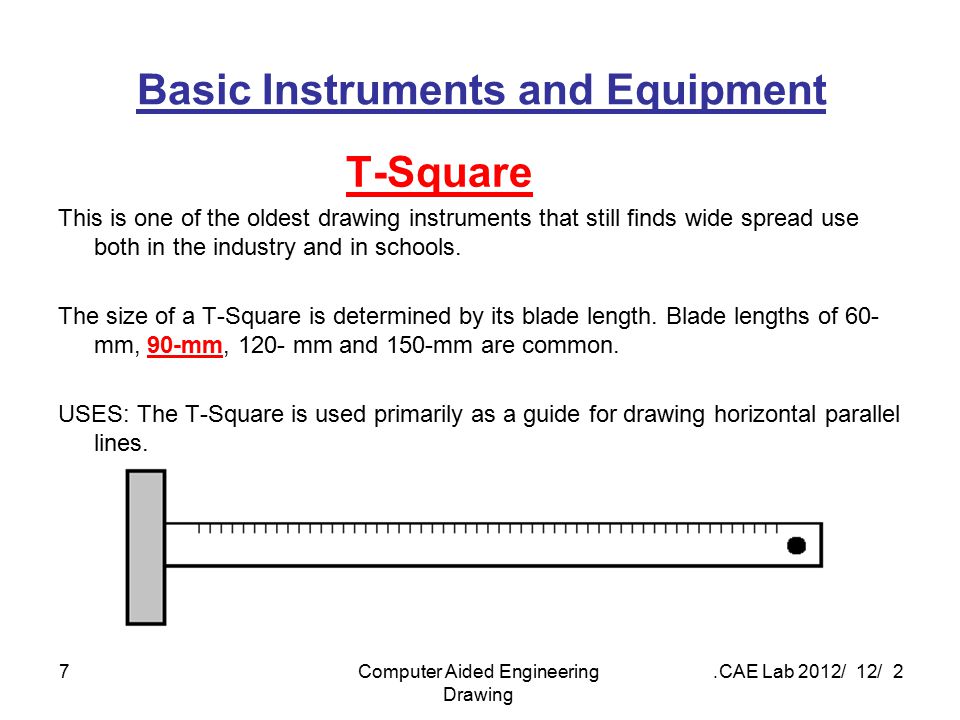

TOPIC: DRAWING PRACTICE

SUB-TOPIC:

1. ISOMETRIC DRAWING

2. OBLIQUE DRAWING

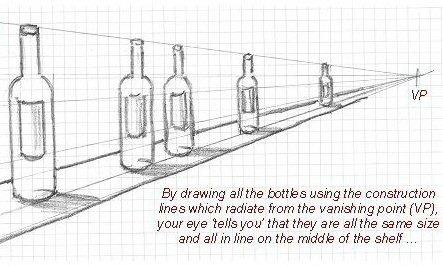

The method of drawing solid objects which shows the three dimensions length, width and depth in one view is called pictorial drawing. The pictorial drawing can be divided into three groups:

(a) The isometric drawing

(b) The oblique drawing

(c) The perspective drawing

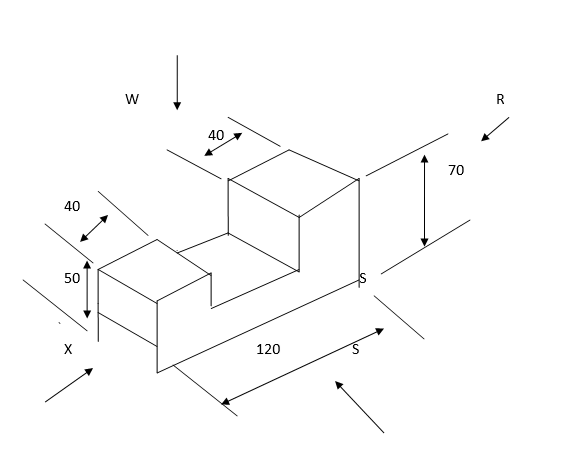

DEFINITION OF ISOMETRIC DRAWING

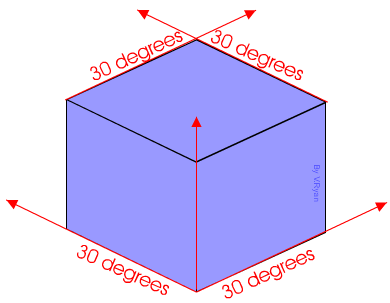

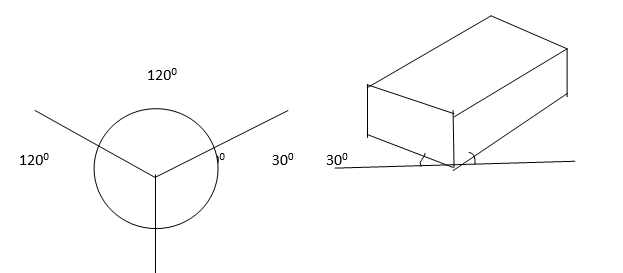

The isometric drawing is the pictorial method of drawing an object in which all the isometric axes are projected to an angle 300 to the horizontal. The isometric drawing shows three axes of an object i.e.

(a) The length

(b) The width

(c) The height